Selecting the optimal compressor technology is critical for the efficiency, safety, and success of your gas handling operations. The choice between diaphragm compressors and piston compressors hinges on specific application requirements, particularly concerning gas purity, pressure, leakage control, and the nature of the gas itself. At Xuzhou Huayan Gas Equipment Co., Ltd., we specialize in designing and manufacturing both advanced diaphragm and robust piston compressors, empowering you with the perfect solution tailored to your unique challenges.

Understanding the Core Technologies:

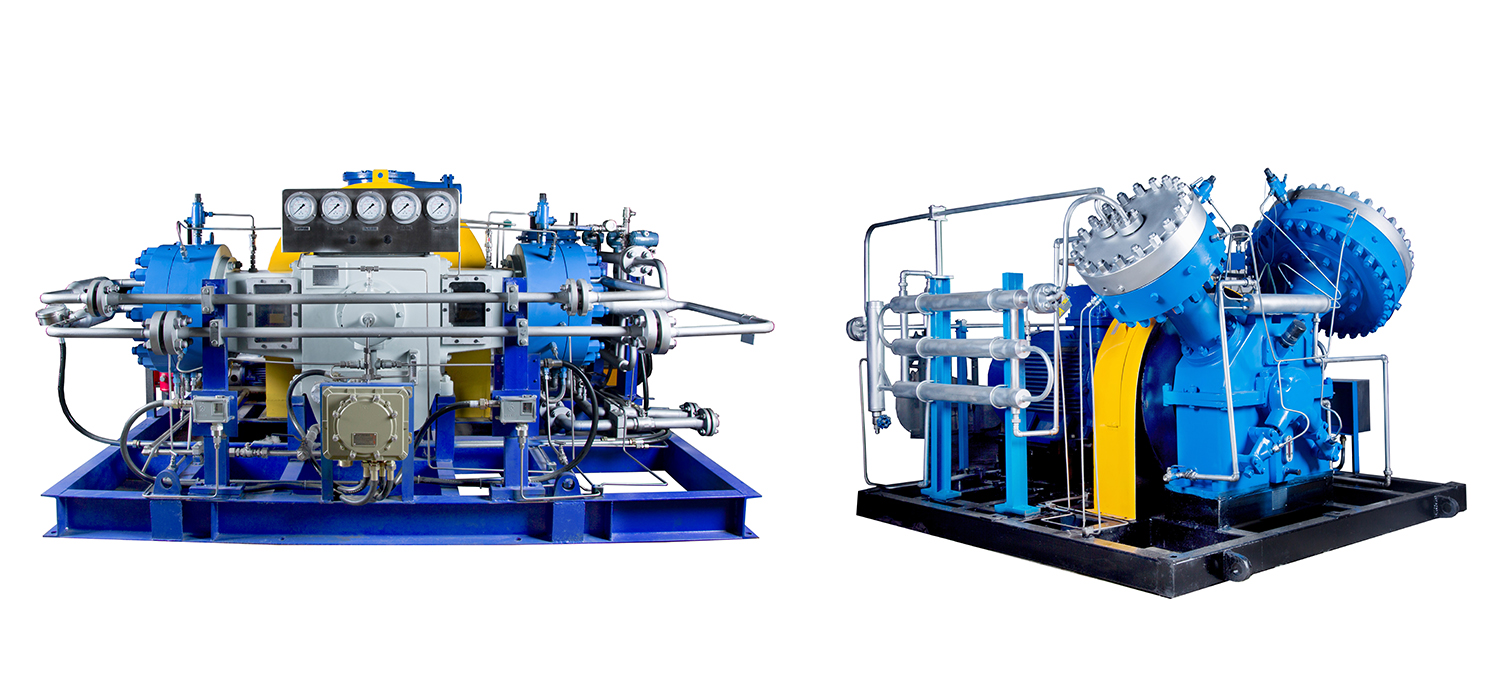

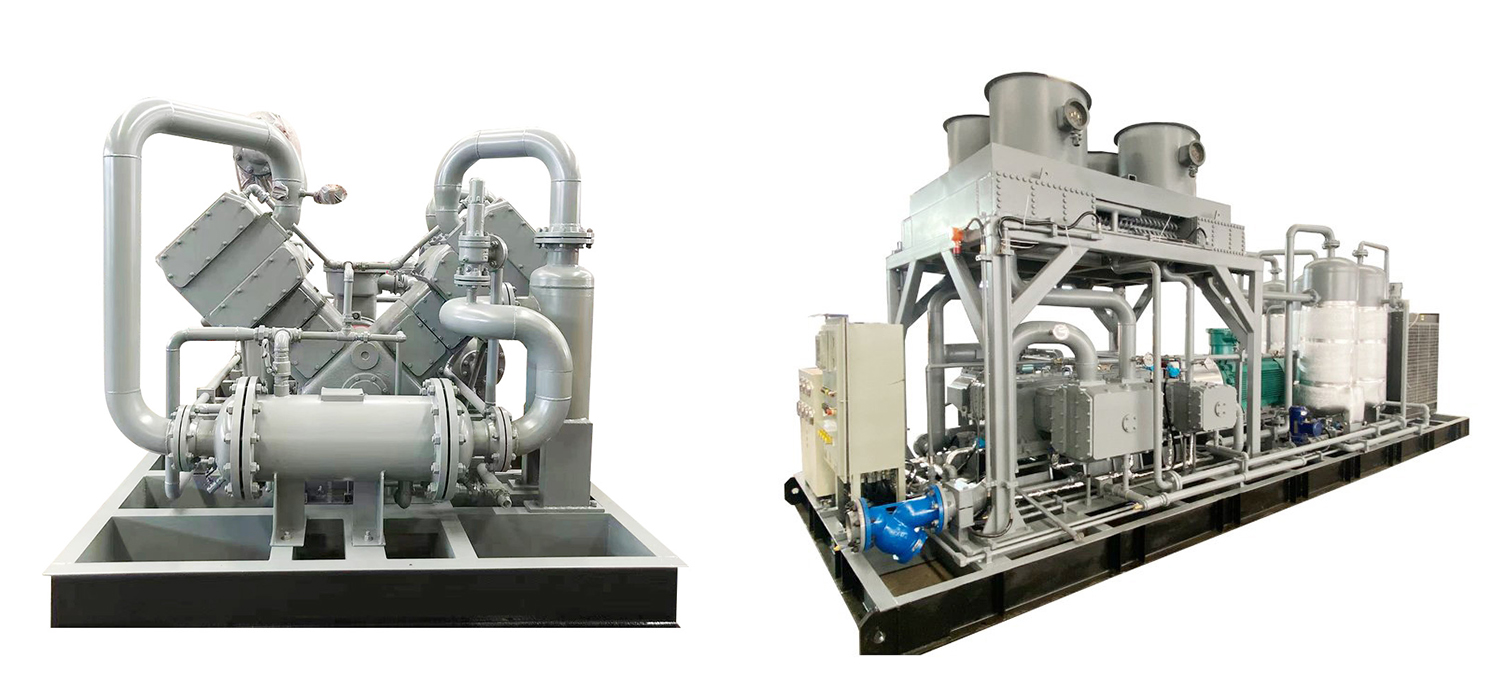

- Diaphragm Compressors: Utilize a flexible metal diaphragm to create a hermetic seal, completely isolating the gas being compressed from the lubricating hydraulic fluid and moving parts. This ensures absolute gas purity (100% oil-free), virtually zero leakage, and exceptional safety for handling hazardous, toxic, explosive, corrosive, or ultra-high-purity gases. They excel in ultra-high-pressure applications, often reaching several hundred to over a thousand bar.

- Piston Compressors: Employ a reciprocating piston within a cylinder to compress gas. They are renowned for their robustness, efficiency (especially at medium-to-large flow rates and conventional high pressures), and cost-effectiveness for a wide range of applications involving standard or inert gases where absolute purity isn’t the paramount concern.

Key Factors Guiding Your Choice:

- Gas Purity & Contamination Sensitivity: Is absolute, guaranteed oil-free and contaminant-free gas essential? (e.g., Semiconductor manufacturing, pharmaceutical processes, fuel cell hydrogen, high-purity analytical gases). → Diaphragm Compressors are the definitive solution.

- Gas Hazard & Value: Are you compressing highly toxic, explosive, pyrophoric, corrosive, radioactive, or extremely valuable/rare gases where any leakage is unacceptable? → Diaphragm Compressors provide unmatched sealing integrity.

- Operating Pressure: Do you require compression into the ultra-high-pressure range (300+ bar, up to 1000+ bar)? → Diaphragm Compressors are specifically engineered for these demanding pressures.

- Flow Rate Requirements: Are your needs focused on smaller to medium flow rates, often associated with high-purity or high-pressure applications? → Diaphragm Compressors are ideal. For larger flow rates at standard high pressures, Piston Compressors offer excellent efficiency.

- Leakage Tolerance: Does your process or environmental regulation demand near-zero leakage rates? → Diaphragm Compressors deliver exceptional leak-tight performance.

Why Partner with Xuzhou Huayan Gas Equipment?

Navigating the diaphragm vs. piston decision requires deep expertise. At Xuzhou Huayan, we are not just manufacturers; we are your trusted partners in gas compression technology. Here’s how we deliver superior value:

- Unrivaled Expertise & Custom Design: Leveraging decades of combined experience, our engineering team possesses profound knowledge of both diaphragm and piston technologies. We don’t just offer standard models; we design and manufacture custom compressors tailored precisely to your gas type, pressure profile (inlet/outlet), flow rate, purity specifications, and site-specific requirements. From metallurgy to sealing systems and control integration, we tailor every aspect.

- In-House R&D & Manufacturing Prowess: We maintain complete control over the entire process – from concept and detailed engineering to precision manufacturing, rigorous testing, and after-sales support. Our state-of-the-art facilities ensure highest quality standards, consistent performance, and reliable delivery for both diaphragm and piston compressor lines. This vertical integration allows for unparalleled flexibility in customization.

- Mastery of Critical Applications: Whether your challenge involves ultra-high-purity electronics gases, hazardous chemical processing, high-pressure hydrogen for energy, or reliable industrial air/gas compression, Xuzhou Huayan has the proven capability and experience to deliver safe, efficient, and durable solutions.

- Commitment to Quality & Reliability: We understand that compressor failure is not an option. Our commitment to using high-grade materials, precision machining, stringent quality control (ISO standards), and thorough testing protocols ensures the long-term reliability and operational safety of every compressor we build.

- Comprehensive Support: Our partnership extends beyond delivery. We offer expert technical consultation during the selection phase, professional installation guidance, comprehensive maintenance training, readily available spare parts, and responsive after-sales service to maximize your compressor’s lifespan and uptime.

Find Your Optimal Gas Compression Solution

Don’t compromise on performance, safety, or efficiency. Whether the stringent demands of your application point decisively towards a hermetically sealed diaphragm compressor or the robust efficiency of a piston compressor is the optimal choice, Xuzhou Huayan Gas Equipment has the expertise, manufacturing capability, and commitment to deliver.

Let our engineers guide you. Provide us with your specific gas, pressure, flow, purity, and operational requirements, and we will recommend the optimal compressor technology and design – diaphragm, piston, or a custom hybrid approach – perfectly engineered for your success.

Ready to optimize your gas handling? Contact Xuzhou Huayan Gas Equipment today for a free consultation!

[Request a Quote]

[Contact Our Engineers]

Xuzhou Huayan Gas Equipment Co., Ltd.

Your Partner in Advanced & Reliable Gas Compression Solutions.

https://www.equipmentcn.com/ | Mail@huayanmail.com |+8619351565170 | 5th Floor, Building 6, Longxi Bay Office Building, Zhongshan Road, Pizhou City, Xuzhou, Jiangsu Province, China

Post time: Jun-07-2025