Key Role of Compression within CCUS Chains

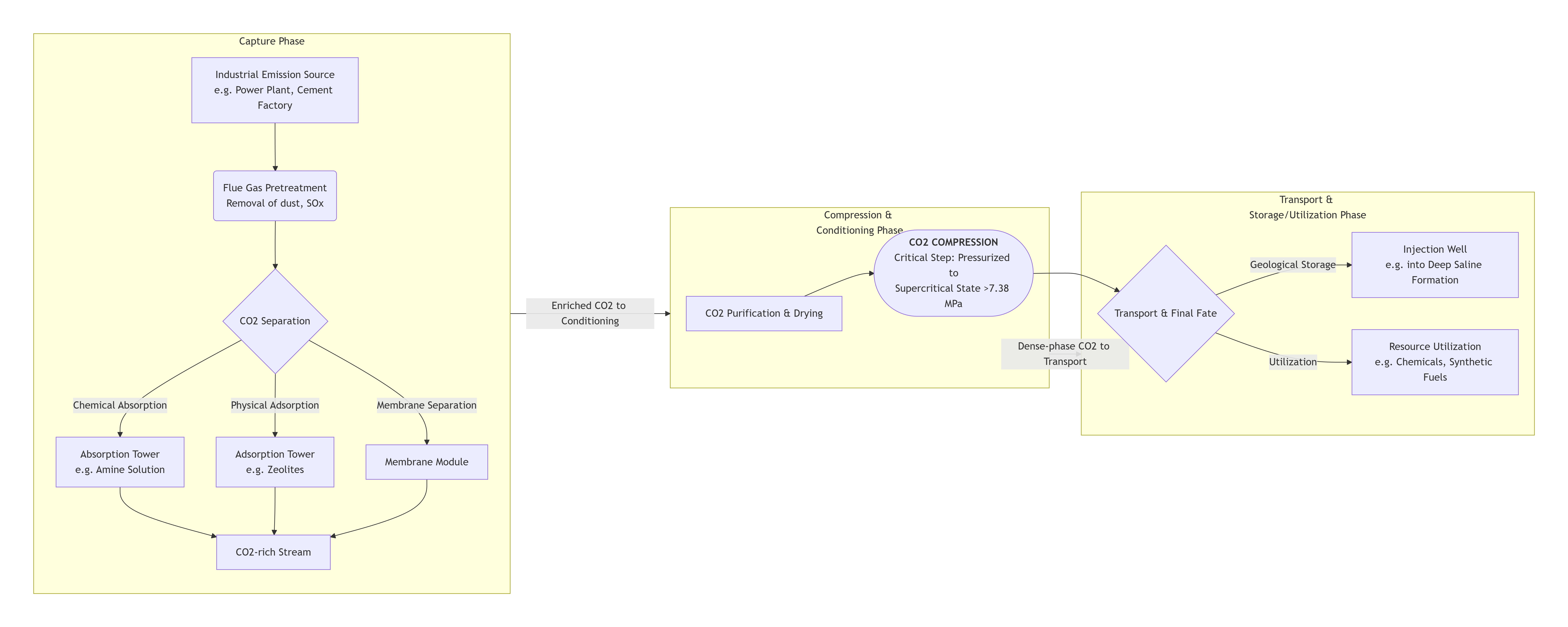

Achieving decarbonization necessitates a phased approach encompassing capturing, transporting, injecting, sealing, emitting, and recovering carbon dioxide.

CCS compression systems play a nontrivial role bridging capture and conveyance while enabling secure containment or conversion. Capture Phase Compression leverages reciprocating compressors and diaphragm compressors, depending upon specifications, to bring CO₂ streams from varied sources to shipment pressures. Following capture, sizes and pressures diverge sharply—typically demanding three- or five-stage reciprocating piston compressors or advanced diaphragm compression systems leveraging specialized materials and seals tolerant of liquefiable, corrosive CO₂ mixtures.

Carbon pipelines then harness reciprocating compressors for general flow boosting supplemented by customized dynamic compressors addressing large-scale feed demands optimized through computational fluid designs and custom-integrated assemblies.

Cost and reliability benchmarks intensify as projects advance from demonstration to commercialization stages, requiring integral involvement of seasoned compression specialists with credentials across simulation/design/manufacturing/commissioning.

Selecting Optimal Compressors for CCS: Key Considerations

Choosing compressors suited for CCS mandates assessing the composition, temperature, molecular weight, and reactivity of handled gases alongside flow range, pressure targets, and environmental standards. Therefore, equipment selection must balance technical feasibility with cost efficiencies.

Matching Compressor Types to CCUS Applications

1. Reciprocating Compressors

- Applicability: Optimal for low-to-medium flow rates with pressures up to 1000 bar

- Advantages: High efficiency, robust pressure flexibility, proven reliability

- Considerations: Periodic maintenance for wear components and motion-induced vibrations

2. Dynamic (Axial/Centrifugal) Compressors

- Applicability: Capable of managing large-scale continuous flow requirements

- Advantages: Reduced operating expenses, minimized maintenance

- Considerations: Requires stable inlet pressures and proactive surge control mechanisms

Medium-Specific Adaptation Capacities

The feasibility of CCS largely demands reliable equipment capable of processing diverse mediums, including volatile mixtures containing CO₂ alongside H₂S/SO₂ or humidity—necessitating customized compression solutions engineered to negate leakage/corrosion/thermal fatigue.

- Gas composition: Concerns involving condensation and liquefaction at phase transitions require pressure/temperature modulation. Gaseous impurities may necessitate specialized seals, lubrication adjustments, or adapted material science formulations.

- Pressure Range: Accommodating incremental fractionation pressures across project complexes requires adaptable compressor staging (spanning atmospheric ingestion to geological injectant specifications).

- Ambient adaptability: Offshore uses mandated reinforced marine-grade assemblies; cold-climate deployments require antifreeze safeguards or heating functions.

- Customization readiness: Facilitates scalable adjustments at demonstration phases, aiding preliminary cost control; commercial plants frequently call for incremental capacity expansions facilitated by compliant compression integration.

- Emissions adherence: Utilizing leak-resistant seals and low-maintenance architectures ensures exact methane emissions compliance essential for CCS carbon accounting credits.

Thus, CCS compressor selection hinges on aligning project-specific specifications with pragmatic customization to optimize both process reliability and long-term economic viability.

Advancing CCS excellence through precision compression design

At Xuzhou Huayan Gas Equipment Co., Ltd. (Huayan), we recognize the critical role compressors play in CCUS systems. With over 40 years of manufacturing excellence, we are committed to pushing the boundaries of compression technology to meet the unique demands of carbon capture.

Our advanced in-house design and engineering approach allows us to create precision compression solutions tailored specifically for challenging CCS applications:

- Specialized Materials: We select materials resistant to corrosion and embrittlement from CO₂ impurities, ensuring longevity in harsh environments.

- Enhanced Sealing: Our proprietary sealing systems minimize leakage risks, maintaining system integrity and reducing fugitive emissions.

- Flexible Configurations: From reciprocating to diaphragm designs, we adapt compression technologies to match the specific phase requirements of CCUS processes.

- Process Integration: We design compressors to work seamlessly with CO₂ drying, purification, and liquefaction systems, optimizing overall CCUS efficiency.

Contact us today to explore how Huayan’s specialized compression expertise can optimize your CCS project performance, reliability, and cost-effectiveness.

Visit our website or connect directly with our technical engineers through www.equipmentcn.com, mail@huayanmail.com, or WhatsApp +86 19351565170.

Post time: Feb-11-2026