Selecting the correct compressor technology is a critical decision that impacts operational efficiency, gas purity, and long-term reliability. Two prominent designs in the industrial gas compression landscape are piston compressors and diaphragm compressors. While both serve the fundamental purpose of increasing gas pressure, their operational methodologies and ideal applications are distinctly different. This guide provides a clear, objective comparison to help you make an informed choice for your specific requirements.

Understanding Piston Compressor Technology

The piston compressor, a widely recognized workhorse, operates on a straightforward reciprocating principle. A motor-driven crankshaft moves pistons within cylinders. During the intake stroke, gas is drawn into the cylinder. The subsequent compression stroke reduces the volume, increasing the gas pressure before it is discharged through valves.

This design is mechanically robust and effective for a broad range of applications, particularly where large volumes of non-critical gases, such as plant air, need to be compressed. However, the design involves inherent points of contact between moving parts (like piston rings and cylinder walls) and the gas stream. This often necessitates lubrication, which can introduce the risk of hydrocarbon contamination. Furthermore, wear over time can lead to internal leakage (blow-by) and potential gas mixing or purity loss.

The Diaphragm Compressor: A Hermetic Sealing Solution

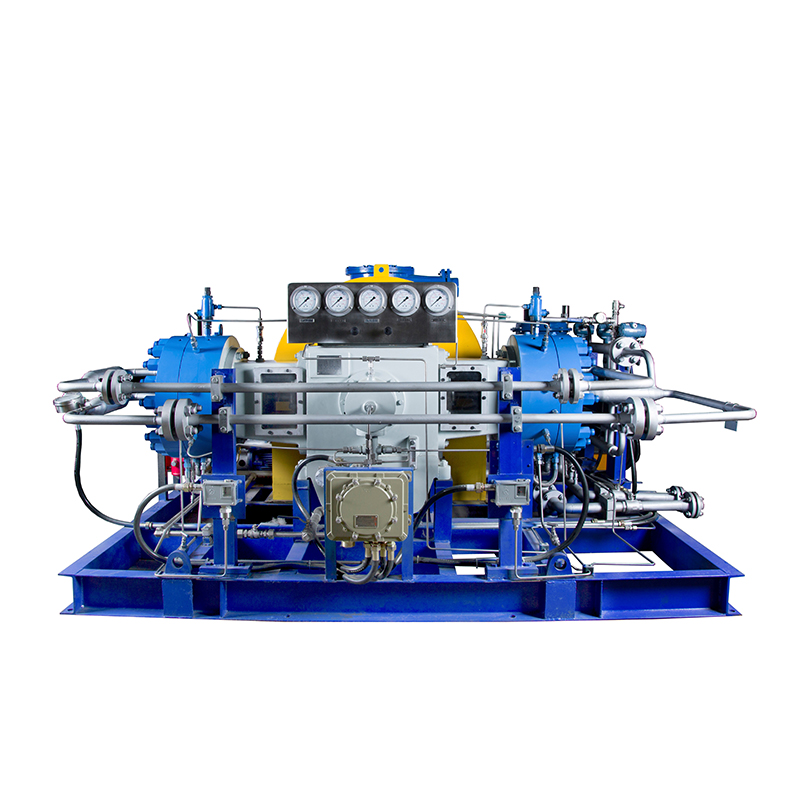

The diaphragm compressor employs an elegantly different principle centered on absolute gas isolation. Its core component is a flexible, multi-layered metal diaphragm that separates the compression chamber into two sections: a hydraulic oil side and a gas side.

A reciprocating piston pumps hydraulic oil, which dynamically flexes the diaphragm. This motion directly compresses the gas on the other side without any physical contact. The gas remains entirely contained within a sealed chamber formed by the diaphragm and the compressor head. This hermetic barrier guarantees that the compressed gas cannot be contaminated by lubricants, and conversely, that the hydraulic system is protected from the process gas.

Critical Comparison: Key Factors for Selection

The choice between these technologies often hinges on a few decisive factors related to the gas and the application’s demands.

- Gas Purity and Contamination Risk:

- Piston: Risk of oil or particle carryover exists. Achieving high purity may require extensive downstream filtration.

- Diaphragm: Zero contamination. The technology is inherently designed for 100% oil-free, pure gas compression, making it mandatory for sensitive processes.

- Gas Type and Safety:

- Piston: Potential for seal leakage makes it less suitable for hazardous, toxic, or expensive gases.

- Diaphragm: The hermetic seal offers exceptional containment. This is the preferred and often required technology for compressing hydrogen, helium, rare gases, toxic specialty gases (e.g., in semiconductors), and flammable gases with maximum safety.

- Maintenance and Operational Life:

- Piston: Maintenance intervals are typically shorter, involving components like piston rings, valves, and seals that are in direct contact with the gas.

- Diaphragm: The gas-side components have an extremely long life with minimal maintenance. Service is primarily focused on the separate, standard hydraulic system.

- Pressure Capability:

- Piston: Capable of achieving high pressures, though very high pressures may require multiple stages with complex sealing.

- Diaphragm: Excels at delivering ultra-high pressures (up to 3000 bar and beyond) reliably in a compact frame, thanks to the robust containment of the diaphragm head.

Where Diaphragm Compressors Are the Essential Choice

Given its defining characteristics, diaphragm compressor technology is indispensable for modern, demanding applications:

- Hydrogen Infrastructure: Electrolyzer gas boosting, hydrogen refueling stations (HRS), and fuel cell testing.

- Semiconductor Fabrication: Handling ultra-high-purity (UHP) and pyrophoric gases.

- Analytical & Laboratory Systems: Providing consistent, clean gas for instruments like GC-MS.

- Medical & Pharmaceutical: Production and packaging of medical-grade gases.

- Specialty Gas & CNG: Compression of high-value, inert, or reactive gases without loss or degradation.

Xuzhou Huayan Gas Equipment: Four Decades of Excellence in Diaphragm Compression

With 40 years of specialized engineering and manufacturing experience, Xuzhou Huayan Gas Equipment Co., Ltd. has established itself as a leading force in diaphragm compressor technology. Our deep expertise allows us to not only build reliable standard units but also to solve unique compression challenges through customized solutions.

Our core competency is complete vertical integration—from design to manufacturing. We control the entire production process, including precision machining of compressor heads, assembly of the hydraulic systems, and meticulous testing. This control is what enables our strong customization capability. We regularly engineer compressors to meet specific client needs regarding gas composition, inlet/outlet pressures, flow rates, material compatibility, and international certification standards.

We invite you to leverage our four decades of experience. Our team is ready to provide technical consultation and develop a diaphragm compressor solution that aligns precisely with your operational goals, ensuring performance, safety, and durability.

For a detailed discussion on how a precisely engineered diaphragm compressor can benefit your project, please contact our technical specialists.

Xuzhou Huayan Gas Equipment Co., Ltd.

Email: Mail@huayanmail.com

Tel/WhatsApp: +86 19351565170

Visit our website for further technical resources.

Post time: Jan-07-2026