Energy-Saving High Purity Psa Nitrogen Generator With Ce and ISO Certification

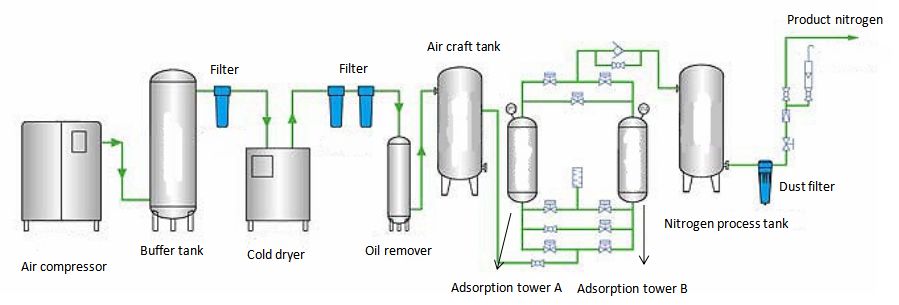

Working principle

After being compressed by an air compressor, the raw air enters the air storage tank after dust removal, oil removal and drying,and then enters the A adsorption tower through the A intake valve. At this time, the tower pressure rises, the nitrogen molecules in the compressed air are adsorbed by the zeolite molecular sieve, and the unadsorbed oxygen passes through the adsorption bed and enters the oxygen buffer tank through the outlet valve. This process is called adsorption. After the adsorption process is over, the adsorption tower A and the adsorption tower B are connected through a pressure equalizing valve to balance the pressure of the two towers. This process is called equalizing pressure. After the pressure equalization is over, the compressed air passes through the B intake valve and enters the B adsorption tower, and the above adsorption process is repeated. At the same time, the oxygen adsorbed by the molecular sieve in the adsorption tower A is decompressed and released into the atmosphere through the exhaust valve A. This process is called desorption, and the saturated molecular sieve is adsorbed and regenerated. Similarly, the right tower is also desorbed when tower A is adsorbing. After the adsorption of Tower B is completed, it will also enter the pressure equalization process, and then switch to the adsorption of Tower A, so that the cycle alternates and continuously produces oxygen.

The above-mentioned basic process steps are all automatically controlled by PLC and automatic switching valve.

Flow Chart

Product Paramenters

|

Model |

Purity |

Capacity |

Air consumption(m³/min) |

Dimensions(mm)L×W×H |

|

HYN-10 |

99 |

10 |

0.5 |

1300×1150×1600 |

|

99.5 |

0.59 |

1350×1170×1600 |

||

|

99.9 |

0.75 |

1400×1180×1670 |

||

|

99.99 |

1.0 |

1480×1220×1800 |

||

|

99.999 |

1.3 |

2000×1450×1900 |

||

|

HYN-20 |

99 |

20 |

0.9 |

1400×1180×1670 |

|

99.5 |

1.0 |

1450×1200×1700 |

||

|

99.9 |

1.4 |

1480×1220×1800 |

||

|

99.99 |

2.0 |

2050×1450×1850 |

||

|

99.999 |

3.0 |

2100×1500×2150 |

||

|

HYN-30 |

99 |

30 |

1.4 |

1400×1180×1670 |

|

99.5 |

1.5 |

1480×1220×1800 |

||

|

99.9 |

2.1 |

2050×1450×1850 |

||

|

99.99 |

2.8 |

2100×1500×2150 |

||

|

99.999 |

4.0 |

2500×1700×2450 |

||

|

HYN-40 |

99 |

40 |

1.8 |

1900×1400×1800 |

|

99.5 |

2.0 |

2000×1450×1900 |

||

|

99.9 |

2.8 |

2100×1500×2050 |

||

|

99.99 |

3.7 |

2200×1500×2350 |

||

|

99.999 |

6.0 |

2600×1800×2550 |

||

|

HYN-50 |

99 |

50 |

2.1 |

2000×1500×1900 |

|

99.5 |

2.5 |

2050×1450×1850 |

||

|

99.9 |

3.3 |

2100×1500×2250 |

||

|

99.99 |

4.7 |

2500×1700×2500 |

||

|

99.999 |

7.5 |

2700×1800×2600 |

||

|

HYN-60 |

99 |

60 |

2.8 |

2050×1450×1850 |

|

99.5 |

3.0 |

2050×1500×2100 |

||

|

99.9 |

4.2 |

2200×1500×2250 |

||

|

99.99 |

5.5 |

2550×1800×2600 |

||

|

99.999 |

9.0 |

2750×1850×2700 |

||

|

HYN-80 |

99 |

80 |

3.7 |

2100×1500×2000 |

|

99.5 |

4.0 |

2100×1500×2150 |

||

|

99.9 |

5.5 |

2500×1700×2550 |

||

|

99.99 |

7.5 |

2700×1800×2600 |

||

|

99.999 |

12.0 |

3200×2200×2800 |

||

|

HYN-100 |

99 |

100 |

4.6 |

2100×1500×2150 |

|

99.5 |

5.0 |

2200×1500×2350 |

||

|

99.9 |

7.0 |

2650×1800×2700 |

||

|

99.99 |

9.3 |

2750×1850×2750 |

||

|

99.999 |

15.0 |

3350×2500×2800 |

||

|

HYN-150 |

99 |

150 |

7.0 |

2150×1470×2400 |

|

99.5 |

7.5 |

2550×1800×2600 |

||

|

99.9 |

10.5 |

2750×1850×2750 |

||

|

99.99 |

14.0 |

3300×2500×2750 |

||

|

99.999 |

22.5 |

3500×3000×2900 |

||

|

HYN-200

|

99 |

200 |

9.3 |

2600×1800×2550 |

|

99.5 |

10.0 |

2700×1800×2600 |

||

|

99.9 |

14.0 |

3300×2500×2800 |

||

|

99.99 |

18.7 |

3500×2700×2900 |

||

|

99.999 |

30.0 |

3600×2900×2900 |

Manufacturing Technique

1. Equipped with air pretreatment equipment such as refrigeration dryer, which effectively guarantees the service life of

molecular sieve.

2. Using high-quality pneumatic valve, short opening and closing time, no leakage, service life of more than 3 million times,

meeting the requirements of frequent use of pressure swing adsorption process, and high reliability.

3. Using PLC control, it can realize fully automatic operation, convenient maintenance, stable performance and low failure rate.

4. The gas production and purity can be adjusted within an appropriate range.

5. Continuously optimized process design, combined with the selection of new molecular sieves, minimizes energy consumption and

capital investment.

6. The device is assembled in a complete set to reduce on-site installation time and ensure quick and easy on-site installation.

7. Compact structure design, less floor space.

Product display

FAQ

1.Are you manufacturer or trade company :

We are the professional manufacturer of oxygen plant with CE and ISO certification.

2.Any guarantee for your products?

All of our products with 12months FREE GUARANTEE,never need to worry about the after-sale service,we will always be here to support your business!

3.How to get a prompt quotation of Nitrogen Generator?

1) Nitrogen flow rate: _____Nm3/hr( or How many cylinders do you want to fill per day(24hours))

2) Nitrogen purity: _____%

3) Nitrogen discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ 5)Altitude : ____

5) Application: ____

4.What is the configuration of oxygen generation system ?

--Air compressor; --Compressed air purification components; --Air buffer tank; --oxygen generator; --Oxygen tank; --Oxygen Sterile filters; --Oxygen Compressor; --Refilling Station; Customized is accepted .

5.Do u support OEM/ODM service?

Yes,we do support.