Abstract: One of the components of the diaphragm compressor is a metal diaphragm, which affects whether the compressor can work for a long time, and it is related to the service life of the diaphragm machine. This article explores the main factors of diaphragm failure in diaphragm compressors and how to extend the service life of the metal diaphragm of the diaphragm compressor by examining the working conditions of the test loop device recovery compressor, the metal diaphragm material and the compressor’s hydraulic oil system.

Keywords: diaphragm compressor; metal diaphragm; cause analysis; countermeasures

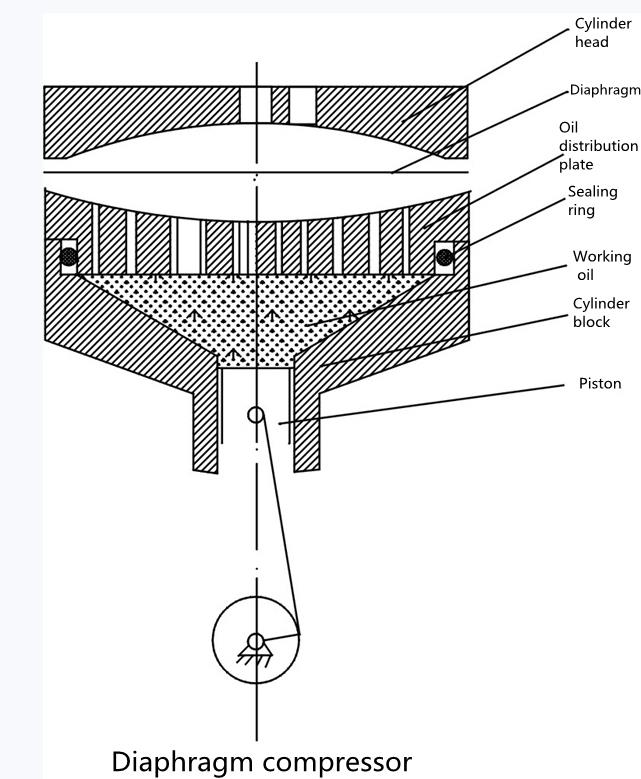

The diaphragm of the diaphragm compressor is mainly for gas operation, so as to achieve the purpose of gas transmission and compression.

Diaphragm is the most used component in compressor operation. The requirements for diaphragm material are very strict.It must have good elasticity and fatigue resistance, so that the service life can be prolonged. Diaphragm rupture occurs, mostly because of improper diaphragm selection and improper operation technology during operation.

The diaphragm compressor of the chemical plant has stricter safety requirements. In addition to meeting the functions required by daily life, the selected diaphragm muscle must also be fully considered in terms of safety. The role of the metal cadmium module is to isolate the process gas from the hydraulic oil and lubricating oil, and to ensure the cleanliness of the compressed gas.

1.Compressor diaphragm failure analysis

The metal diaphragm compressor is a reciprocating diaphragm compressor. During the normal operation of the compressor, the liquid in the cylinder will be driven by the diaphragm. There are three types of diaphragm failure in the inside of the diaphragm compressor.

① When the membrane head pressure is too high, it will reach a high interlock value shutdown state; in the event of a failure, the pressure at the outlet of the compressor will reach the pressure that the high interlock value can withstand, and the interlock will stop.

②The pressure at the outlet of the compressor is lower than the set pressure value, and the reaction is terminated because the initiator is not sufficiently injected. When the compressor pressure is decreasing, at the same time, the valve position of the pressure regulating valve at the outlet will gradually increase. The valve position will lose its regulating performance and reach 100%. When the outlet pressure is lower than the specified MPa pressure, its reaction will be affected, and even termination will occur.

③When the diaphragm is in chain operation, it will trigger a chain shutdown. Since the compressor is installed and used, it has been in normal operation. Since the selected recovery compressor is a set of experimental devices, there are many states of compressor startup and shutdown, and the working conditions of the diaphragm are also more complicated when the experiment is carried out. In a long-term operation, it can be found that the service life of the metal diaphragm is only less than half of the service life under normal operation. In particular, the service life of the second-stage compression diaphragm of the compressor is extremely short; the diaphragm on the oil side of the compressor is more severely damaged in winter. The diaphragm of the compressor is often damaged, and finally caused frequent shutdown and inspection during the test, which causes a lot of inconvenience.

1. The compressor diaphragm appears, and the premature damage has the following aspects.

1.1 Compressor oil temperature is too low

When the temperature is lower than the freezing point in winter, the viscosity of the hydraulic oil is higher than during normal operation. The pilot loop tube device of this compressor is a test tube device, and this device is frequently used during startup and shutdown, and the compressor’s startup and shutdown frequency is also relatively high. This compressor does not have a system for heating the oil temperature. When the hydraulic press is first started, the temperature of the oil pressure is too low and the viscosity is too high due to climatic reasons, which causes the oil pressure of the hydraulic oil to be too low and the hydraulic oil system is not good. Was established. During operation, the compressed gas in the compressor will make the diaphragm close to the orifice plate in every operation link, and the pressure of the gas will cause the diaphragm to constantly impact, resulting in partial deformation of the oil guide hole, the diaphragm will rupture before it reaches the specified service life.

1.2 Compressor working condition

According to the gas partial pressure theory, it is easy to liquefy under the fixed temperature and pressure of the work, which causes the original gas inside the compressor to liquefy, and the metal diaphragm will be impacted by the liquid phase, which will cause the diaphragm to appear prematurely. Damage.

1.3 Compressor diaphragm material

The material used for the compressor diaphragm is a material that has been specially treated and has good mechanical properties. The disadvantage of this is that the corrosion resistance will be weaker. However, when the pilot ring tube is produced There will be a small amount of corrosive medium that has not undergone chemical reactions, and enters the recovery system without special-shaped treatment. The compressor diaphragm faces this problem. At that time, when choosing the diaphragm material, the thickness was only 0.3mm, so the strength would be relatively weak.

2. Measures to extend the service life of the compressor diaphragm

The service life of the diaphragm of a diaphragm compressor is very important. When the performance of the compressor meets the standard, the reliability of the compressor is judged by the service life of the metal diaphragm. The factors that can affect the life of the diaphragm include the following aspects, such as the nature of the compressed gas, the stability of the hydraulic oil, and the material of the diaphragm. The reason for the premature breakage of the compression diaphragm machine was analyzed and an improvement plan was developed.

2.1 Increase hydraulic oil electric heating system

The oil tank of the compressor needs electricity to generate heat, and it is necessary to determine whether to use oil heating according to the ambient temperature. In winter, when the temperature reaches the freezing point and is lower than 18 degrees Celsius, the hydraulic oil should be automatically heated by electricity. When the temperature is higher than 60 degrees, the electric heating switch should be automatically turned off, and the outdoor temperature should be kept in line with the heating at all times. Standard to prevent diaphragm impact damage caused by low oil pressure and temperature

2.2 Optimizing process conditions

The pilot loop pipe should be appropriately optimized and improved according to the compressor operating conditions. On the premise of ensuring the stable operation of the subsequent system, the outlet temperature of the compressor must be increased, and the outlet pressure of the compressor must be appropriately reduced. Prevent the liquid phase impact caused by the liquefaction of n-hexane, and extend the service life of the metal diaphragm.

2.3 Reforming the metal diaphragm

To re-select the material of the metal diaphragm, it is necessary to choose a material with high toughness, high strength, and good corrosion resistance. The processing technology of the metal diaphragm should also be improved.

①In order to improve the strength, corrosion resistance and willfulness of the material, the material should be treated with aging.

②After the machine is completed, in order to reduce the pressure inside the metal diaphragm as much as possible, it is necessary to polish both sides of the diaphragm.

③To increase the service life of the diaphragm, it is necessary to apply anti-corrosion materials on both sides of the middle part of the diaphragm to prevent the diaphragm from rubbing against each other and causing corrosion.

④The thickness of the diaphragm is increased to increase the strength of the diaphragm, and the service life of the diaphragm will be prolonged.

Conclusion In the above test process, the diaphragm of the compressor has been improved and its working conditions have been optimized. In the actual operation of the diaphragm compressor, the service life of the metal diaphragm is prolonged, which promotes the diaphragm compressor to be able to last for a long time.

Post time: Nov-30-2021