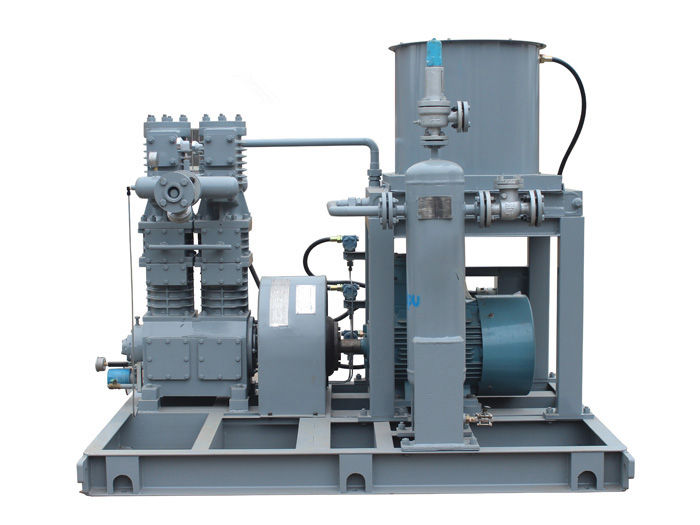

The flow pattern of the small air-cooled piston compressor can be traced back to the early 19th century. They are widely used in various equipment, the highest pressure can reach 1.2MPa. Air-cooled units of various sizes can be adapted to the wilderness environment.

The most common small piston compressor is single-acting. The exhaust temperature can reach 240°C, and most of the unit's operating noise exceeds 80dBA.

For low-power units, because the initial investment cost is 40-60% less than that of screw compressors, piston compressors have higher use value. Here also need to consider other auxiliary equipment, such as secondary cooler, starter and shutdown switch, these costs are to be included in the total price.

Small piston compressors can provide reasonable high-quality compressed air for many equipment in a long life time. Simple design, wide operating range and high reliability are their most important strengths.

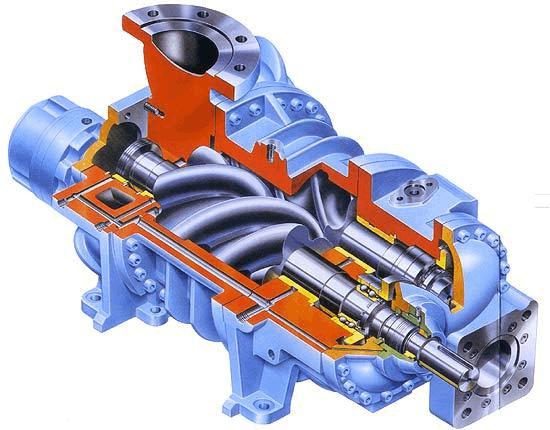

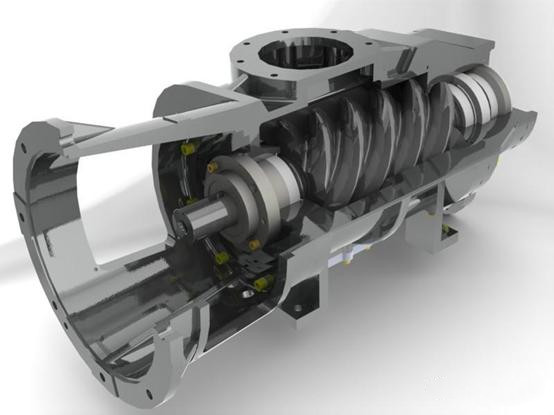

Although the initial investment of screw compressors is more expensive than piston compressors, they are becoming more and more popular in the power range of 7.4-22kW. One reason is that screw units are usually packaged as modules. In most cases, the standard screw unit module is packaged with a starter, an aftercooler, and a compressor controller with capacity monitoring capabilities.

Screw compressors can also be used in a smaller power range, from 3.7 to 22kW. Under the same power condition, one advantage over piston compressors is that their exhaust temperature is lower. The screw compressor is designed to work under a 100% load cycle, with low lubricating oil and providing high-quality compressed air.

Install

Small piston compressors need to be equipped with gas storage tanks. The air storage tank is used to store compressed air and reduce the load operation time of the compressor. Some small piston compressors usually operate within approximately 66% of the working (load) cycle time.

The life of a piston engine with a sufficiently large gas tank is particularly important. Regardless of the size of the gas tank or the structure of the compressor and the gas tank, the installation of a small piston compressor is always easy. Due to unbalanced forces, any piston compressor should be fixed on the ground.

Most screw machine modules are designed to be independently movable, and their installation foundation can even be placed on the top of the gas tank. There is no pulsation in the discharge of the screw compressor. Nevertheless, the system including the air storage tank is very beneficial for the smooth return of the air signal to the compressor controller and the stable operation of the system.

Small screw compressors can provide users with the entire box, which can be used in compressed air systems that require constant air volume. The operating noise level of most enclosed screw units is lower than 80dBA. The packaged screw compressor can be easily installed on the floor, and usually only a single-point connection device is used to connect electricity and gas.

Choosing the right installation space is critical to the reliability and long service life of the air-cooled compressor. Good air flow through the compressor body is a necessary condition for the good operation and long life of the machine.

In general, the compressed air quality of screw compressors is better. Even if it is an oil-lubricated screw unit, the high-efficiency oil-gas separator can reduce the oil content discharged into the compressed air system to 5ppm. At the same time, the inherently lower exhaust temperature of the screw machine can further improve the quality of compressed air. The exhaust temperature of most screw units is only about 50°C higher than the ambient temperature.

Post time: Dec-03-2021