OEM Oxygen Filling Station Manufacturer – Medical oxygen Generator Plant for filling cylinders – Huayan

OEM Oxygen Filling Station Manufacturer – Medical oxygen Generator Plant for filling cylinders – Huayan Detail:

XUZHOU HUAYAN GAS EQUIPMENT CO.,LTD oxygen generator adopts Pressure Swing Adsorption technology to produce oxygen from compressed air .

HYO series Oxygen Generators are available in different standard models with capacity ranging from 3.0Nm3/h to 150 Nm3/hour at 93% ±2 purity .The design is made for round the clock 24/7 operation .

Features :

- Lower Air Consumption

- High Efficiency 4 – Stage Filtration Package

- SIEMENS PLC Controller

- Interactive HMI Full Colour touch screen

- High Performance True Process Valves

- Skid-Mounted

Application:

- Hospital

- Aquaculture

- Feed Gas for Ozone Generators

- Glass blowing

- Oxygen Lancing

- Industrial application : Metal Welding, Brazing

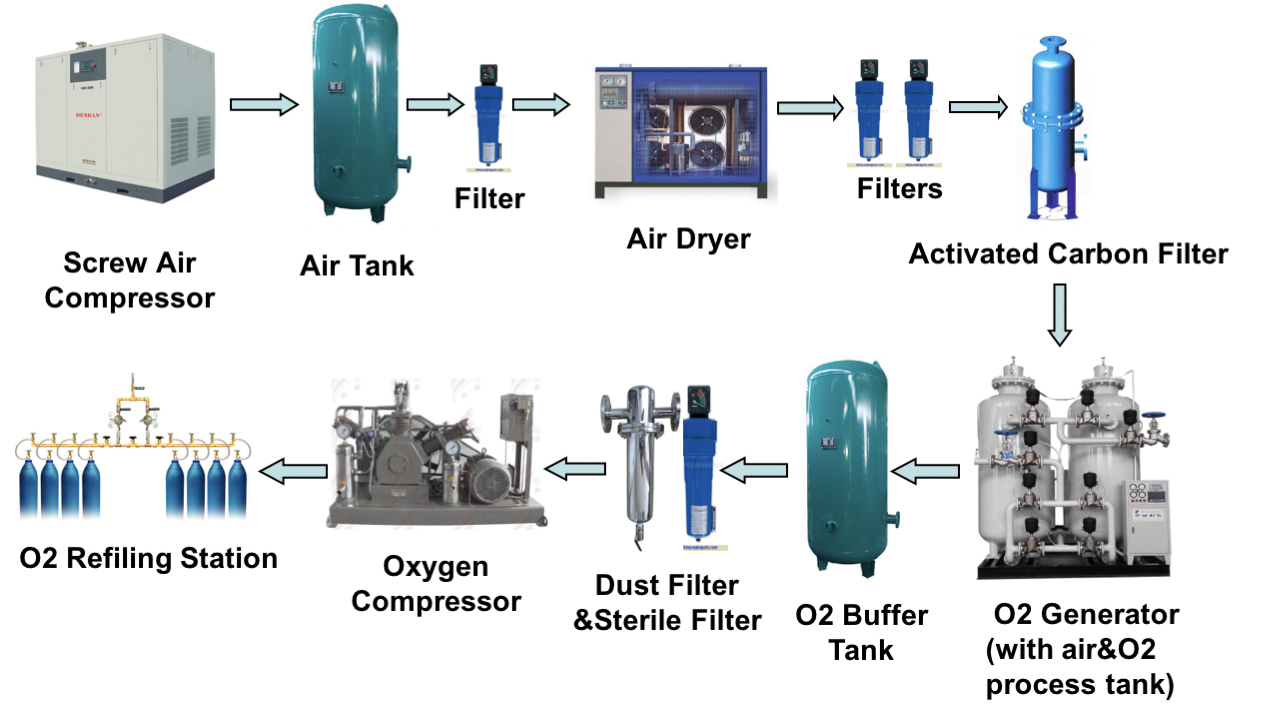

Flow Chart of PSA Oxygen Generator

The compressed air from the air compressor enters the storage tank after dust removal, oil removal and drying, and enters the left adsorption tower through the air inlet valve and the left air inlet valve. When the pressure in the tower rises, the nitrogen molecules in the compressed air are adsorbed by the zeolite molecular sieve, and the non-adsorbed oxygen passes through the adsorption bed and enters the oxygen storage tank through the left gas production valve and oxygen production valve. After the left adsorption is finished, the left adsorption tower is connected to the right one by the pressure equalizing valve to reach the equilibrium pressure. The compressed air then enters the right adsorption tower through the air inlet valve and the right air inlet valve. When the pressure in the tower rises, the nitrogen molecules in the compressed air are adsorbed by the zeolite molecular sieve, and the un-adsorbed oxygen enters the oxygen adsorption tower through the adsorption bed. Oxygen that has not been adsorbed enters the adsorption tower through the adsorption bed. Oxygen that has passed through the adsorption tower enters the buffer tank in front of the booster, then flows into the oxygen booster to increase the pressure to 150 bar or 200 bar, and then is filled into the oxygen cylinder through the filling row.

The Oxygen Generator System is consisted by .Air Compressor , Air Receive Tank ,Refrigerant Dryer &Precision Filters , Oxygen Generator ,Oxygen Buffer Tank , Sterile Filter,Oxygen Booster,Oxygen Filling Station .

Model and Specification

|

MODEL |

PRESSURE |

OXYGEN FLOW |

PURITY |

CAPACITY FOR FILLING CYLINDERS PER DAY |

|

|

40L /150bar |

50L /200bar |

||||

|

HYO-3 |

150/200BAR |

3Nm³/h |

93%±2 |

12 |

7 |

|

HYO-5 |

150/200BAR |

5Nm³/h |

93%±2 |

20 |

12 |

|

HYO-10 |

150/200BAR |

10Nm³/h |

93%±2 |

40 |

24 |

|

HYO-15 |

150/200BAR |

15Nm³/h |

93%±2 |

60 |

36 |

|

HYO-20 |

150/200BAR |

20Nm³/h |

93%±2 |

80 |

48 |

|

HYO-25 |

150/200BAR |

25Nm³/h |

93%±2 |

100 |

60 |

|

HYO-30 |

150/200BAR |

30Nm³/h |

93%±2 |

120 |

72 |

|

HYO-40 |

150/200BAR |

40Nm³/h |

93%±2 |

160 |

96 |

|

HYO-45 |

150/200BAR |

45Nm³/h |

93%±2 |

180 |

108 |

|

HYO-50 |

150/200BAR |

50Nm³/h |

93%±2 |

200 |

120 |

|

HYO-60 |

150/200BAR |

60Nm³/h |

93%±2 |

240 |

144 |

How to get a quote ? — In order to give you exact quotation , below information is required :

1.O2 flow rate :______Nm3/h (how many cylinders do you want to fill per day(24 hours)

2.O2 purity :_______%

3.O2 discharge pressure :______ Bar

4.Voltages and Frequency : ______ V/PH/HZ

5.Application : _______

Product detail pictures:

Related Product Guide:

Our staff are usually in the spirit of "continuous improvement and excellence", and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer's belief for OEM Oxygen Filling Station Manufacturer – Medical oxygen Generator Plant for filling cylinders – Huayan , The product will supply to all over the world, such as: San Francisco, Danish, Curacao, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.