CO2 Piston Reciprocating Booster Compressor

Low Pressure and High Pressure CO2 compressor

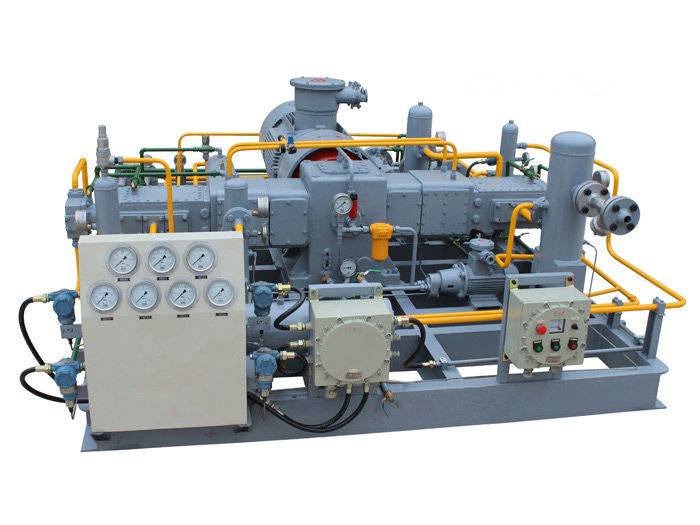

Reciprocating compressor is a kind of piston reciprocating motion to make gas pressurization and gas delivery compressor mainly consists of working chamber, transmission parts, body and auxiliary parts. The working chamber is directly used to compress the gas, the piston is driven by the piston rod in the cylinder for reciprocating motion, the volume of the working chamber on both sides of the piston changes in turn, the volume decreases on one side of the gas due to the pressure increase through the valve discharge, the volume increases on one side due to the reduction of air pressure through the valve to absorb the gas.

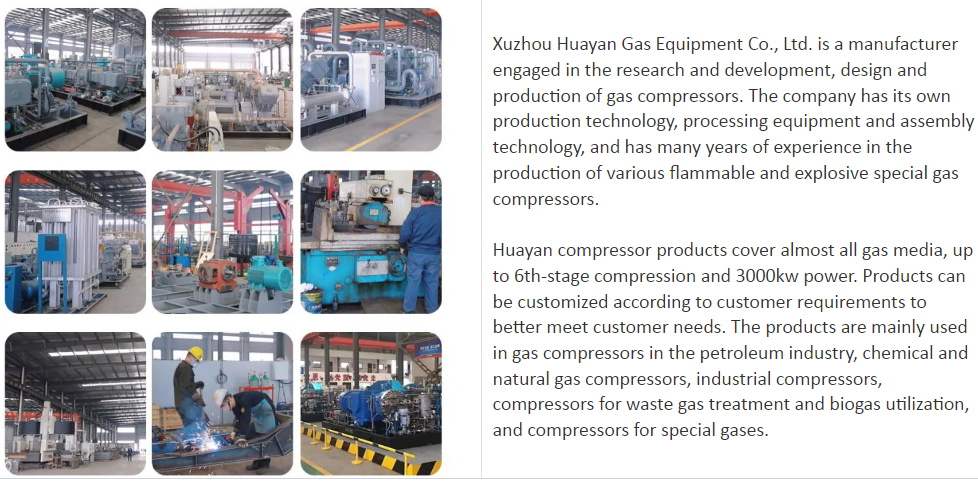

We have various gas compressors, such as Hydrogen compressor, Nitrogen compressor, Natural gas compressor, Biogas compressor, Ammonia compressor, LPG compressor, CNG compressor, Mix gas compressor and so on.

Product parameters

1. Z-type vertical: displacement ≤ 3m3/min, pressure 0.02MPa-4Mpa (selected according to actual needs)

2. D-type symmetrical type: displacement ≤ 10m3/min, pressure 0.2MPa-2.4Mpa (selected according to actual needs)

3. The V-shaped exhaust volume ranges from 0.2m3/min to 40m3/min. The exhaust pressure ranges from 0.2MPa to 25MPa (selected according to actual needs)

Product Features

1. The product has the characteristics of low noise, low vibration, compact structure, smooth operation, safety and reliability, and high automation level. It can also be configured with a data-driven remote display and control system according to customer requirements.

2. Equipped with alarm and shutdown functions for low oil pressure, low water pressure, high temperature, low inlet pressure, and high exhaust pressure of the compressor, making the operation of the compressor more reliable.

Structure Introduction

The unit consists of a compressor host, electric motor, coupling, flywheel, pipeline system, cooling system, electrical equipment, and auxiliary equipment.

Lubrication method

1. No oil 2. Oil available (selected based on actual needs)

Cooling method

1. Water cooling 2. Air cooling 3. Mixed cooling (selected according to actual needs)

Overall structural form

Fixed, mobile, pry mounted, soundproof shelter type (selected according to actual needs)

Application of CO2 compressor

Carbon dioxide (CO2) is a widely used gas with multiple uses and applications. Here are some common carbon dioxide applications:

Beverage and food industry:. It can increase the bubbles and taste of beverages, and extend the shelf life of food.

Medical industry: It is often used as an anesthetic, for respiratory therapy and artificial ventilation, as well as for endoscopic surgery and tissue freezing.

Fire extinguishing: It can effectively extinguish flames without causing short circuits in electrical equipment.

Gas shield welding: It can form a protective layer in the welding area to prevent oxygen from entering and reduce oxidation reactions.

Supercritical fluid extraction: This method is widely used in industries such as food, medicine, and cosmetics.

Enhanced oil recovery: Injecting carbon dioxide can increase the pressure in the oil well and drive the flow of oil to the producing well.

Foam extinguishing agent: This kind of foam can effectively extinguish the flammable liquid fire and form an isolation layer to prevent the spread of fire.

These are just some common applications of carbon dioxide, which also have important applications in other fields and processes. Although carbon dioxide is useful in many ways, we also need to pay attention to controlling and reducing carbon dioxide emissions to address climate change and environmental challenges.

HYDROGEN COMPRESSOR-PARAMETER TABLE

|

Number |

Model |

Flow-rate(Nm3/h) |

Inlet pressure(Mpa) |

Exhaust pressure(Mpa) |

Medium |

Motor power(kw) |

Overall dimensions(mm) |

|

1 |

ZW-0.5/15 |

24 |

Normal pressure |

1.5 |

Hydrogen |

7.5 |

1600*1300*1250 |

|

2 |

ZW-0.16/30-50 |

240 |

3 |

5 |

Hydrogen |

11 |

1850*1300*1200 |

|

3 |

ZW-0.45/22-26 |

480 |

2.2 |

2.6 |

Hydrogen |

11 |

1850*1300*1200 |

|

4 |

ZW-0.36 /10-26 |

200 |

1 |

2.6 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

5 |

ZW-1.2/30 |

60 |

Normal pressure |

3 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

6 |

ZW-1.0/1.0-15 |

100 |

0.1 |

1.5 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

7 |

ZW-0.28/8-50 |

120 |

0.8 |

5 |

Hydrogen |

18.5 |

2100*1350*1150 |

|

8 |

ZW-0.3/10-40 |

150 |

1 |

4 |

Hydrogen |

22 |

1900*1200*1420 |

|

9 |

ZW-0.65/8-22 |

300 |

0.8 |

2.2 |

Hydrogen |

22 |

1900*1200*1420 |

|

10 |

ZW-0.65/8-25 |

300 |

0.8 |

25 |

Hydrogen |

22 |

1900*1200*1420 |

|

11 |

ZW-0.4/(9-10)-35 |

180 |

0.9-1 |

3.5 |

Hydrogen |

22 |

1900*1200*1420 |

|

12 |

ZW-0.8/(9-10)-25 |

400 |

0.9-1 |

2.5 |

Hydrogen |

30 |

1900*1200*1420 |

|

13 |

DW-2.5/0.5-17 |

200 |

0.05 |

1.7 |

Hydrogen |

30 |

2200*2100*1250 |

|

14 |

ZW-0.4/(22-25)-60 |

350 |

2.2-2.5 |

6 |

Hydrogen |

30 |

2000*1600*1200 |

|

15 |

DW-1.35/21-26 |

1500 |

2.1 |

2.6 |

Hydrogen |

30 |

2000*1600*1200 |

|

16 |

ZW-0.5/(25-31)-43.5 |

720 |

2.5-3.1 |

4.35 |

Hydrogen |

30 |

2200*2100*1250 |

|

17 |

DW-3.4/0.5-17 |

260 |

0.05 |

1.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

18 |

DW-1.0/7-25 |

400 |

0.7 |

2.5 |

Hydrogen |

37 |

2200*2100*1250 |

|

19 |

DW-5.0/8-10 |

2280 |

0.8 |

1 |

Hydrogen |

37 |

2200*2100*1250 |

|

20 |

DW-1.7/5-15 |

510 |

0.5 |

1.5 |

Hydrogen |

37 |

2200*2100*1250 |

|

21 |

DW-5.0/-7 |

260 |

Normal pressure |

0.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

22 |

DW-3.8/1-7 |

360 |

0.1 |

0.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

23 |

DW-6.5/8 |

330 |

Normal pressure |

0.8 |

Hydrogen |

45 |

2500*2100*1400 |

|

24 |

DW-5.0/8-10 |

2280 |

0.8 |

1 |

Hydrogen |

45 |

2500*2100*1400 |

|

25 |

DW-8.4/6 |

500 |

Normal pressure |

0.6 |

Hydrogen |

55 |

2500*2100*1400 |

|

26 |

DW-0.7/(20-23)-60 |

840 |

2-2.3 |

6 |

Hydrogen |

55 |

2500*2100*1400 |

|

27 |

DW-1.8/47-57 |

4380 |

4.7 |

5.7 |

Hydrogen |

75 |

2500*2100*1400 |

|

28 |

VW-5.8/0.7-15 |

510 |

0.07 |

1.5 |

Hydrogen |

75 |

2500*2100*1400 |

|

29 |

DW-10/7 |

510 |

Normal pressure |

0.7 |

Hydrogen |

75 |

2500*2100*1400 |

|

30 |

VW-4.9/2-20 |

750 |

0.2 |

2 |

Hydrogen |

90 |

2800*2100*1400 |

|

31 |

DW-1.8/15-40 |

1500 |

1.5 |

4 |

Hydrogen |

90 |

2800*2100*1400 |

|

32 |

DW-5/25-30 |

7000 |

2.5 |

3 |

Hydrogen |

90 |

2800*2100*1400 |

|

33 |

DW-0.9/20-80 |

1000 |

2 |

8 |

Hydrogen |

90 |

2800*2100*1400 |

|

34 |

DW-25/3.5-4.5 |

5700 |

0.35 |

0.45 |

Hydrogen |

90 |

2800*2100*1400 |

|

35 |

DW-1.5/(8-12)-50 |

800 |

0.8-1.2 |

5 |

Hydrogen |

90 |

2800*2100*1400 |

|

36 |

DW-15/7 |

780 |

Normal pressure |

0.7 |

Hydrogen |

90 |

2800*2100*1400 |

|

37 |

DW-5.5/2-20 |

840 |

0.2 |

2 |

Hydrogen |

110 |

3400*2200*1300 |

|

38 |

DW-11/0.5-13 |

840 |

0.05 |

1.3 |

Hydrogen |

110 |

3400*2200*1300 |

|

39 |

DW-14.5/0.04-20 |

780 |

0.004 |

2 |

Hydrogen |

132 |

4300*2900*1700 |

|

40 |

DW-2.5/10-40 |

1400 |

1 |

4 |

Hydrogen |

132 |

4200*2900*1700 |

|

41 |

DW-16/0.8-8 |

2460 |

0.08 |

0.8 |

Hydrogen |

160 |

4800*3100*1800 |

|

42 |

DW-1.3/20-150 |

1400 |

2 |

15 |

Hydrogen |

185 |

5000*3100*1800 |

|

43 |

DW-16/2-20 |

1500 |

0.2 |

2 |

Hydrogen |

28 |

6500*3600*1800 |