High Purity Oil Free Diaphragm Compressor Helium Oxygen Hydrogen Gas Compressor

Reciprocating Complete Oil-Free Diaphragm/Piston Compressor

Our company specialize in making various kinds of compressors, such as:Diaphragm compressor,Piston compressor, Air compressors,Nitrogen generator,Oxygen generator ,Gas cylinder,etc. All products can be customized according to your parameters and other requirements.

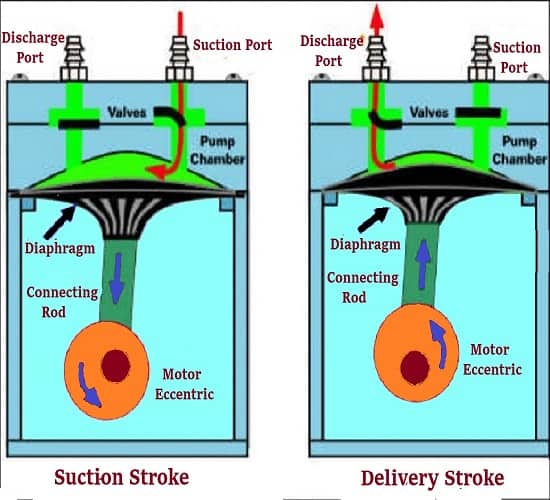

The diaphragm compressor is a volume compressor of a special structure. It is the highest -level compression method in the field of gas compression. This compression method does not have secondary pollution. It has very good protection for the compressed gas. Good sealing, compressed gas is not polluted by lubricating oil and other solid impurities. Therefore, it is suitable for compressing high purity, rare precious, flammable and explosive, toxic and harmful, corrosive, and high pressure gas.

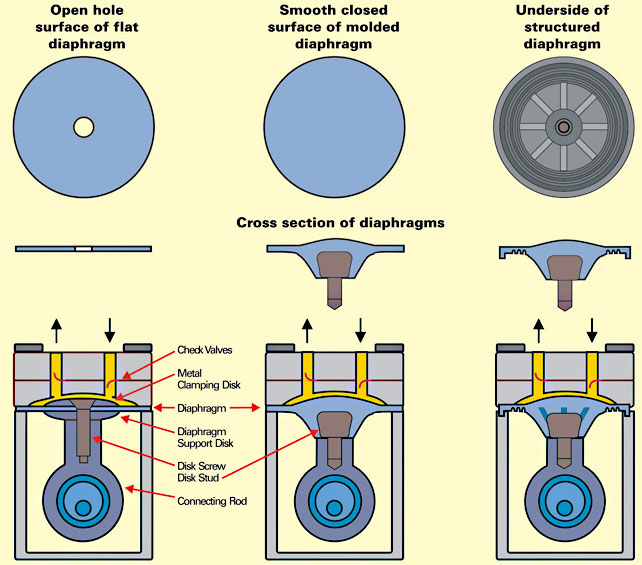

diaphragm compressor is a variant of the classic reciprocating compressor with backup and piston rings and rod seal. The compression of gas occurs by means of a flexible membrane, instead of an intake element. The back and forth moving membrane is driven by a rod and a crankshaft mechanism. Only the membrane and the compressor box come in touch with pumped gas. For this reason this construction is the best suited for pumping toxic and explosive gases. The membrane has to be reliable enough to take the strain of pumped gas. It must also have adequate chemical properties and sufficient temperature resistance.

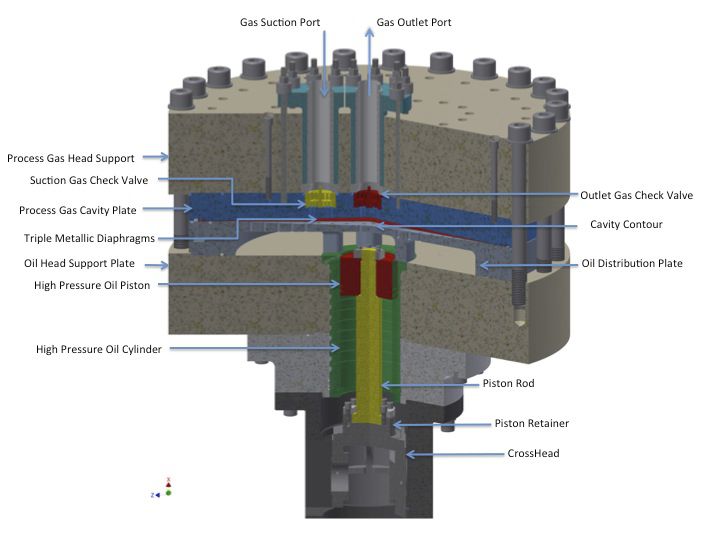

The diaphragm compressor is mainly composed of motors, bases, crankshaft boxes, crankshaft connecting rods, cylinder components, oil and gas pipelines, electrical control systems, and some accessories.

The compressor is consists of a three pieces of diaphragms. The diaphragm is clamped along the surrounding area by the hydraulic oil side and the process gas side of the process. The diaphragm is driven by the hydraulic driver in the film head to achieve the compression and transportation of the gas. The main body of the diaphragm compressor consists of two systems: the hydraulic oil system and the gas compression system, and the metal membrane separates these two systems.

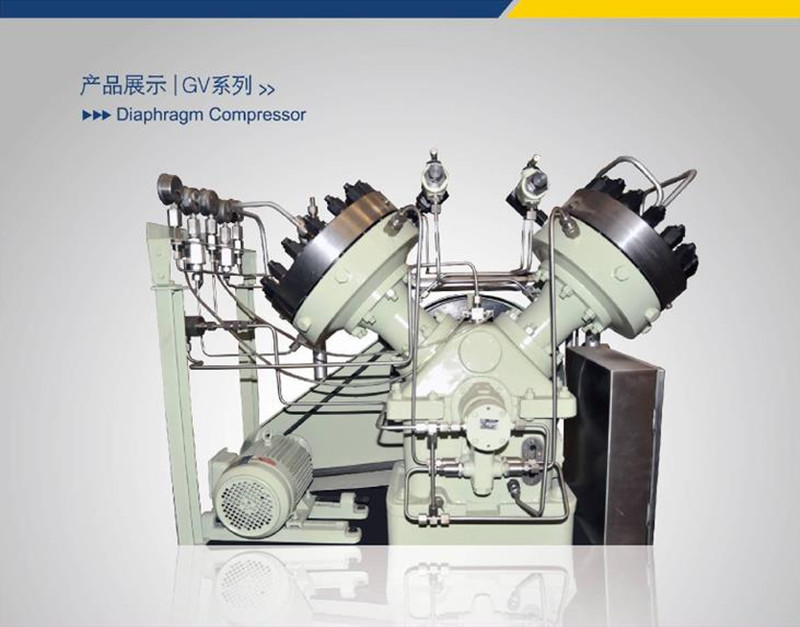

GV series diaphragm compressor :

Structure type : V type

Piston Travel : 70-130mm

Max Piston force : 10KN-30KN

Max discharge Pressure : 50MPa

Flow Rate Range :2-100Nm3/h

Motor Power : 2.2KW-30KW

Customized is accepted , Pls provide the following information to us :

1.Flow rate: _______Nm3/h

2.Gas Media : ______ Hydrogen or Natural Gas or Oxygen or other gas ?

3.Inlet pressure: ___bar(g)

4.Inlet temperature:_____℃

5.Outlet pressure:____bar(g)

6.Outlet temperature:____℃

7.Installation location: _____indoor or outdoor?

8.Location ambient temperature: ____℃

9.Power supply: _V/ _Hz/ _3Ph?

10.Cooling method for gas: air cooling or water cooing?

Wide variety and types of diaphragm compressor can be manufactured by our company such as hydrogen compressor , nitrogen compressor , helium compressor , natural gas compressor and etc .

Outlet pressure at 50bar 200 bar, 350 bar (5000 psi), 450 bar, 500 bar, 700 bar (10,000 psi), 900 bar (13,000 psi) and other pressure can be customized .

GV Model Table

| Number | Model | Cooling water consumption(t/h) | Exhaust volume Nm3/h) |

Intake pressure (MPa) |

Exhaust pressure (MPa) |

Overall dimension LxWxH(mm) |

Weight (t) |

Motor power (KW) |

| The piston stroke of the following products is 70mm | ||||||||

| 1 | GV-8/8-160 | 0.5 | 8 | 0.8 | 16 | 1310x686x980 | 0.65 | 3 |

| 2 | GV-10/6-160 | 0.8 | 10 | 0.6~0.7 | 16 | 1200x600x1100 | 0.5 | 4 |

| 3 | GV-10/8-160 | 0.8 | 10 | 0.8 | 16 | 1330x740x 1080 | 0.65 | 4 |

| 4 | GV-10/4-160 | 0.8 | 10 | 0.4 | 16 | 1330x740x1000 | 0.65 | 4 |

| 5 | GV-7/8-350 | 0.8 | 7 | 0.8 | 16 | 1300x610x920 | 0.8 | 4 |

| 6 | GV-15/5-160 | 0.8 | 15 | 0.5 | 16 | 1330x740x920 | 0.7 | 5.5 |

| 7 | GV-5/7-350 | 1 | 5 | 0.7 | 35 | 1400x845x1100 | 0.8 | 5.5 |

| The piston stroke of the following products is 95mm | ||||||||

| 8 | GV-5/200 | 0.4 | 5 | Normal pressure | 20 | 1500x780x1080 | 0.75 | 3 |

| 9 | GV-5/1-200 | 0.3 | 5 | 0.1 | 20 | 1520 x 800 x 1050 | 0.75 | 3 |

| 10 | GV-11/1-25 | 0.6 | 11 | 0.1 | 2.5 | 1500x780x1080 | 0.85 | 4 |

| 11 | GV-12/2-150 | 1 | 12 | 0.2 | 15 | 1600x776x1080 | 0.75 | 5.5 |

| 12 | GV-20/W-160 | 0.8 | 20 | 1 | 16 | 1500x800x 1200 | 0.8 | 5.5 |

| 13 | GV-30/5-30 | 0.8 | 30 | 0.5 | 1 | 1588x 768 x 1185 | 0.98 | 5.5 |

| 14 | GV-10/1-40 | 0.4 | 10 | 0.1 | 4 | 1475 x 580x1000 | 1 | 5.5 |

| 15 | GV-20/4 | 0.6 | 20 | Normal pressure | 0.4 | 1500x900x1100 | 1 | 5.5 |

| 16 | GV-70/5-10 | 1-5 | 70 | 0.5 | 1 | 1595 x 795 x 1220 | 1 | 5.5 |

| 17 | GV-8/5-210 | 0.4 | 8 | 0.5 | 21 | 1600 x 880x1160 | 1.02 | 5.5 |

| 18 | GV-20/1-25 | 0.4 | 20 | 0.1 | 2.5 | 1450 x 840x1120 | 1.05 | 5.5 |

| 19 | GV-20/10 - 350 | 1.2 | 20 | 1 | 35 | 1500x750x1140 | 0.8 | 7.5 |

| 20 | GV-15/5-350 | 1-05 | 15 | 0.5 | 35 | 1600 x 835x 1200 | 1 | 7.5 |

| 21 | GV-20/8-250 | 1.2 | 20 | 0.8 | 25 | 1520x825x1126 | 1 | 7.5 |

| 22 | GV-12/5-320 | 1.2 | 12 | 0.5 | 32 | 1600 x 835x 1130 | 1 | 7.5 |

| 23 | GV-15/8-350 | 1.1 | 15 | 0.8 | 35 | 1520x820x1160 | 1.02 | 7.5 |

| 24 | GV-18/10-350 | 1.2 | 18 | 1 | 35 | 1255 x 800 x 1480 | 1.2 | 7.5 |

| 25 | GV-35/4-25 | 0.3 | 35 | 0.4 | 2.5 | 1500x810x1100 | 1 | 7.5 |

| 26 | GV-50/6.5-36 | 2.25 | 50 | 0.65 | 3.6 | 1450x850x1120 | 1.048 | 7.5 |

| 27 | GV-20/5-200 | 1-2 | 20 | 0.5 | 20 | 1500x780x1080 | 0.8 | 7.5 |

| The piston stroke of the following products is 130mm | ||||||||

| 28 | GV-20/3-200 | 1.2 | 20 | 0.3 | 20 | 2030 x 1125 x 1430 | 1.8 | 15 |

| 29 | GV-25/5 -160 | 1.2 | 25 | 0.5 | 16 | 1930 x 1150 x 1450 | 1.8 | 15 |

| 30 | GV-40/0.5-10 | 1.2 | 40 | 0.05 | 1.00 | 2035 x 1070 x 1730 | 1.8 | 15 |

| 31 | GV-20/200 | 1.2 | 20 | Normal pressure | 20 | 1850 x 1160 x 1400 | 1.85 | 15 |

| 32 | GV-90/30-200 | 1.2 | 90 | 3 | 20 | 2030 x 970 x 1700 | 1-8 | 22 |

| 33 | GV-30/8-350 | 2.4 | 30 | 0.8 | 35 | 2030 x 1125 x 1430 | 1.8 | 22 |

| 34 | GV-30/8-350 | 2.4 | 30 | 0.8 | 35 | 2040 x 1125 x 1430 | 1.8 | 22 |

| 35 | GV-60/10-160 | 3 | 60 | 1 | 16 | 1800 x 1100 x 1400 | 1.8 | 22 |

| 36 | GV-60/5-160 | 3 | 60 | 0.5 | 16 | 2030 x 1125 x 1430 | 1.8 | 22 |

| 37 | GV-40/10-400 | 2 | 40 | 1 | 40 | 2000 x 1150 x 1500 | 1.8 | 22 |

| 38 | GV-60/10-350 | 2.4 | 60 | 1 | 35 | 2070 x 1125 x 1430 | 1.8 | 22 |

| 39 | GV-30/5-350 | 2 | 30 | 0.5 | 35 | 1900 x 1130 x 1450 | 2 | 22 |

| 40 | GV-40/2.5-160 | 2 | 40 | 0.25 | 16 | 1900 x 1130 x 1450 | 2 | 22 |

| 41 | GV-150/3.5-30 | 2 | 150 | 0.35 | 3 | 1900 x 1130 x 1450 | 2 | 22 |

| 42 | GV-70/2.5-80 | 2 | 70 | 0.25 | 8 | 1880 x 1060 x 1400 | 2.12 | 22 |

| 43 | GV-80/2.5-80 | 2 | 80 | 0.25 | 8 | 1880 x 1060 x 1400 | 2.12 | 22 |

| 44 | GV-120/3.5-12 | 3.6 | 120 | 0.35 | 1.2 | 2030 x 1045 x 1700 | 2.2 | 22 |

| 45 | GV-100/7-25 | 1.2 | 100 | 0.7 | 2.5 | 2030 x 1045 x 1700 | 1.9 | 30 |

| 46 | GV-50/5-210 | 2 | 50 | 0.5 | 21 | 1900 x 1130 x 1450 | 2 | 30 |

| 47 | GV-80/5-200 | 2 | 80 | 0.5 | 20 | 1900 x 1130 x 1450 | 2 | 22 |

| 48 | GV-40/5-350 | 2 | 40 | 0.5 | 35 | 1900 x 1130 x 1450 | 2 | 30 |

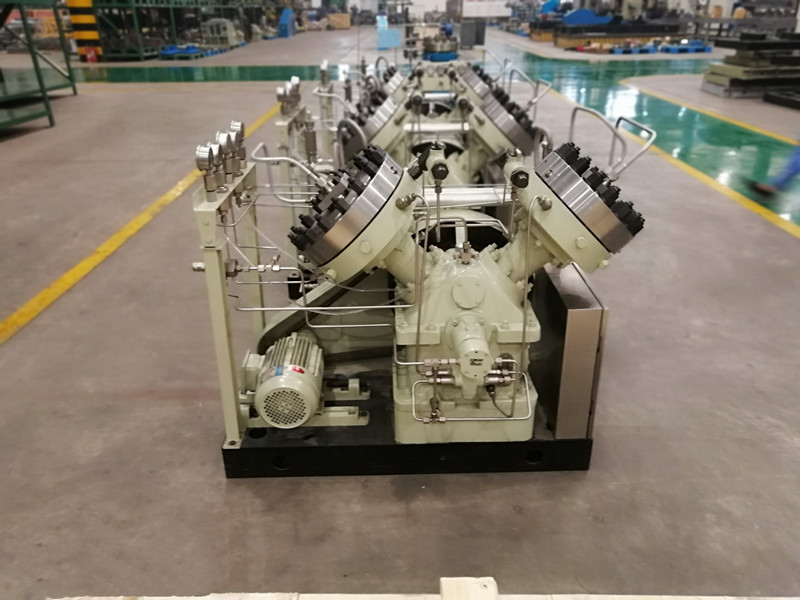

Picture display

RFQ

1.How to get a prompt quotation of gas compressor ?

1)Flow Rate/Capacity : ___ Nm3/h

2)Suction/ Inlet Pressure : ____ Bar

3)Discharge/Outlet Pressure :____ Bar

4)Gas Medium :_____

5)Voltage and Frequency : ____ V/PH/HZ

2.How long is delivery time ?

Delivery time is around the 30-90 days .

3.What about the voltage of products? Can they be customized?

Yes, the voltage can be customized according to your inquire.

4.Can you accept OEM orders?

Yes, OEM orders is highly welcome.

5.Will you provide some spare parts of the machines?

Yes, we will .