Psa Plant For Oxygen Manufacturers – HY-20 Generating Equipment Zeolite Molecular Sieve Oxygen Plant Mobile Oxygen Generator for Refilling Cyliner – Huayan

Psa Plant For Oxygen Manufacturers – HY-20 Generating Equipment Zeolite Molecular Sieve Oxygen Plant Mobile Oxygen Generator for Refilling Cyliner – Huayan Detail:

Our company specialize in making various kinds of compressors, such as:Diaphragm compressor,Piston compressor, Air compressors,Nitrogen generator,Oxygen generator ,Gas cylinder,etc. All products can be customized according to your parameters and other requirements.

Working principle

After being compressed by an air compressor, the raw air enters the air storage tank after dust removal, oil removal and drying, and then enters the A adsorption tower through the A intake valve. At this time, the tower pressure rises, the nitrogen molecules in the compressed air are adsorbed by the zeolite molecular sieve, and the unadsorbed oxygen passes through the adsorption bed and enters the oxygen buffer tank through the outlet valve. This process is called adsorption. After the adsorption process is over, the adsorption tower A and the adsorption tower B are connected through a pressure equalizing valve to balance the pressure of the two towers. This process is called equalizing pressure. After the pressure equalization is over, the compressed air passes through the B intake valve and enters the B adsorption tower, and the above adsorption process is repeated. At the same time, the oxygen adsorbed by the molecular sieve in the adsorption tower A is decompressed and released into the atmosphere through the exhaust valve A. This process is called desorption, and the saturated molecular sieve is adsorbed and regenerated. Similarly, the right tower is also desorbed when tower A is adsorbing. After the adsorption of Tower B is completed, it will also enter the pressure equalization process, and then switch to the adsorption of Tower A, so that the cycle alternates and continuously produces oxygen. The above-mentioned basic process steps are all automatically controlled by PLC and automatic switching valve.

Technical characteristics

1. Equipped with air pretreatment equipment such as refrigeration dryer, which effectively guarantees the service life of molecular sieve.

2. Using high-quality pneumatic valve, short opening and closing time, no leakage, service life of more than 3 million times, meeting the requirements of frequent use of pressure swing adsorption process, and high reliability.

3. Using PLC control, it can realize fully automatic operation, convenient maintenance, stable performance and low failure rate.

4. The gas production and purity can be adjusted within an appropriate range.

5. Continuously optimized process design, combined with the selection of new molecular sieves, minimizes energy consumption and capital investment.

6. The device is assembled in a complete set to reduce on-site installation time and ensure quick and easy on-site installation.

7. Compact structure design, less floor space.

Model Parameter

| MODEL | PRESSURE | OXYGEN FLOW | PURITY | CAPACITY CYLINDERS/DAY | |

| 40L | 50L | ||||

| HYO-3 | 150/200BAR | 3Nm3/h | 93% ±2 | 12 | 7 |

| HYO-5 | 150/200BAR | 5Nm3/h | 93%±2 | 20 | 12 |

| HYO-IO | 150/200BAR | 10Nm3/h | 93% ±2 | 40 | 24 |

| HYO-15 | 150/200BAR | 15Nm3/h | 93% ±2 | 60 | 36 |

| HYO-20 | 150/200BAR | 20Nm3/h | 93% ±2 | 80 | 48 |

| HYO-25 | 150/200BAR | 25Nm3/h | 93% ±2 | 100 | 60 |

| HYO-30 | 150/200BAR | 30Nm3/h | 93% ±2 | 120 | 72 |

| HYO-40 | 150/200BAR | 40Nm3/h | 93%±2 | 160 | 96 |

| HYO-45 | 150/200BAR | 45Nm3/h | 93% ±2 | 180 | 108 |

| HYO-50 | 150/200BAR | 50Nm3/h | 93% ±2 | 200 | 120 |

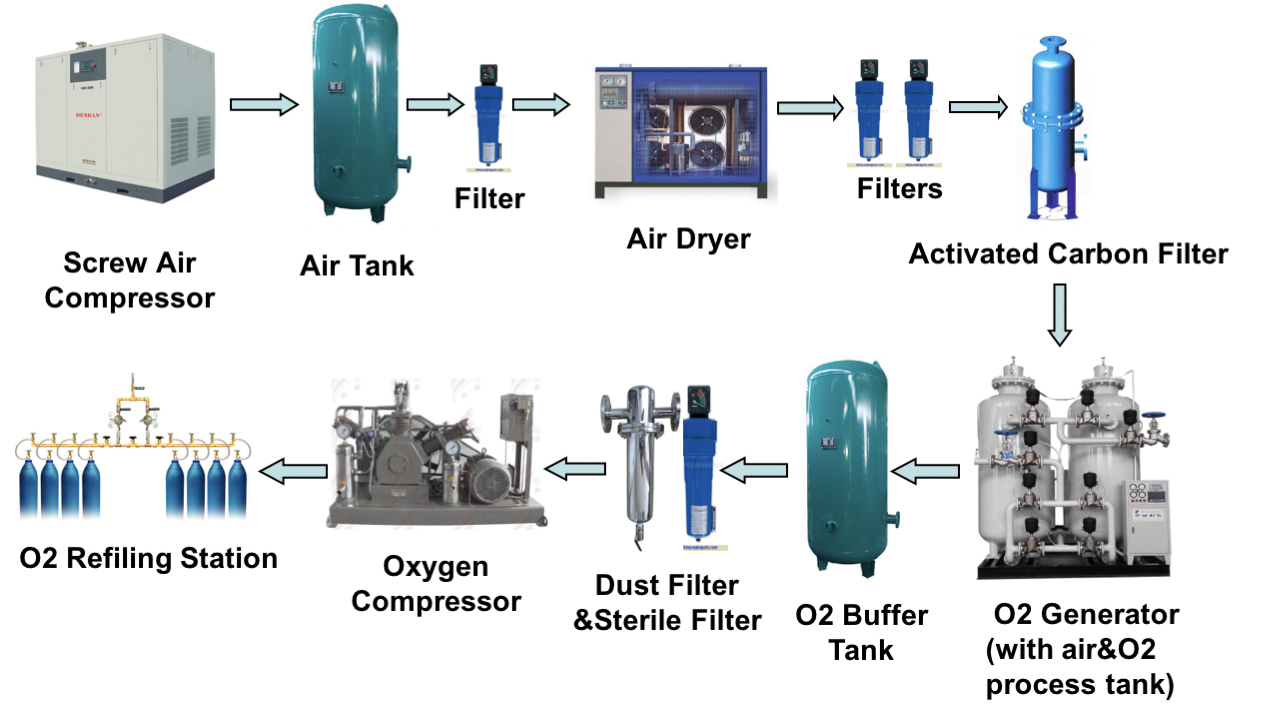

Oxygen Production Porcess

How to get a quote ? — In order to give you exact quotation , below information is required :

1.O2 flow rate :______Nm3/h (how many cylinders do you want to fill per day(24 hours)

2.O2 purity :_______%

3.O2 discharge pressure :______ Bar

4.Voltages and Frequency : ______ V/PH/HZ

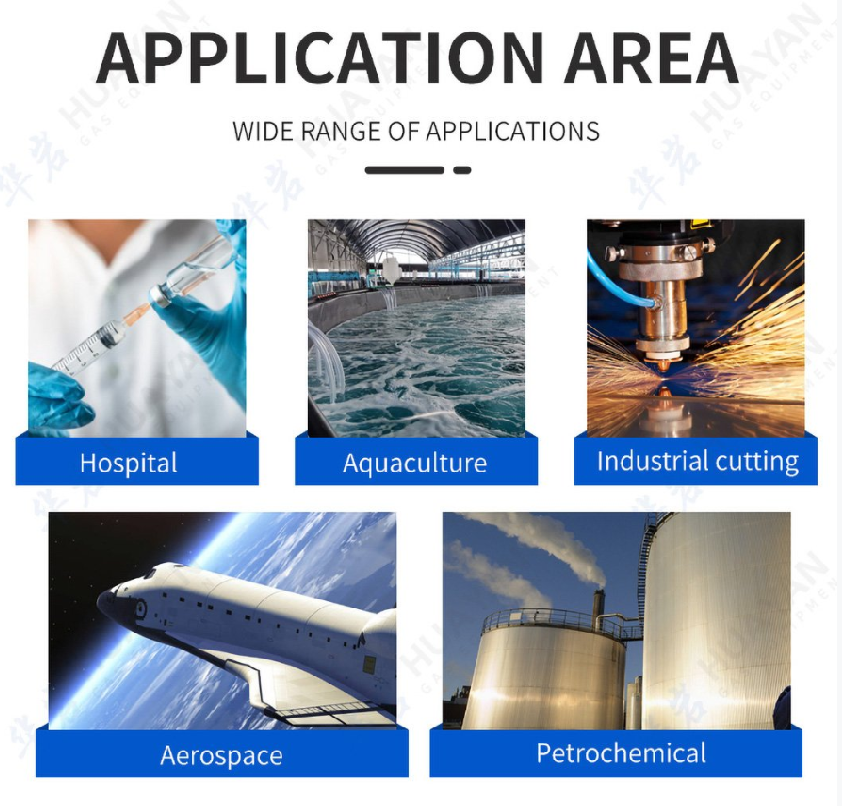

5.Application : _______

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Price and Efficient Service" for Psa Plant For Oxygen Manufacturers – HY-20 Generating Equipment Zeolite Molecular Sieve Oxygen Plant Mobile Oxygen Generator for Refilling Cyliner – Huayan , The product will supply to all over the world, such as: Uzbekistan, Norwegian, Madras, Our items have national accreditation requirements for qualified, high quality goods, affordable value, was welcomed by people today all over the world. Our products will continue to enhance within the order and look forward to cooperation with you, Should really any of these products and solutions be of curiosity to you, be sure to letus know. We are likely to be content to offer you a quotation up on receipt of your detailed needs.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.