G130D High Pressure Hydrogen Diaphragm Compressors

Xuzhou Huayan Gas Equipment Co., Ltd. is a premier global provider of gas compression solutions. With accumulated expertise in design and manufacturing spanning decades, our company possesses comprehensive production capabilities encompassing professional forging, casting, heat treatment, welding, precision machining, assembly testing, and quality verification processes. Supported by a dedicated technical team of 120 professionals and a sprawling 90,000 m² manufacturing facility, we maintain advanced technical testing equipment and rigorous quality control methods to ensure superior product performance.

Capable of custom-designing, manufacturing, and installing equipment according to specific customer parameters, we currently achieve an annual production capacity of 500 gas compressor units. Our technical excellence enables the development of compressors with discharge pressures up to 100MPa, meeting the most demanding industrial requirements.

With a global footprint extending to over 50 countries across five continents, including key markets such as Indonesia, Egypt, Vietnam, South Korea, Thailand, Finland, Australia, Czech Republic, Ukraine, and Russia, we deliver complete turnkey solutions for clients worldwide. Our commitment to operational excellence ensures every customer receives high-performance equipment paired with professional technical support and responsive service.

SQUARE METER

TECHNICAL TEAM

MANUFACTURING EXPERIENCE

EXPORTING COUNTRIES

A diaphragm compressor is a specialized positive displacement compressor renowned for its ability to handle gases with exceptional purity, sensitivity, or hazard without contamination or leakage. Unlike traditional piston compressors, it utilizes a flexible, hydraulically actuated diaphragm to isolate the compressed gas from the lubricated crankcase and piston.

Key Features:

1、Hermetic Sealing: The metal or elastomer diaphragm creates a complete, leak-proof barrier between the gas and the hydraulic fluid/lubricants. This is its defining characteristic.

2、Zero Contamination: Guarantees the compressed gas remains absolutely oil-free and uncontaminated by lubricants or wear particles from the drive mechanism. Essential for high-purity applications.

3、Leak Prevention: Virtually eliminates fugitive emissions, making it critical for handling toxic, flammable, explosive, or environmentally harmful gases.

4、High Pressure Capability: Capable of achieving very high discharge pressures (often up to 3000 bar / 43,500 psi and beyond), especially in multi-stage configurations.

5、Versatile Gas Handling: Suitable for compressing a wide range of gases, including highly reactive, corrosive, ultra-pure, expensive, or hazardous types that would damage or be contaminated by other compressor designs.

6、Moderate Flow Rates: Typically designed for low to medium flow rates compared to large reciprocating or centrifugal compressors.

Suitable Gases

Suitable Gases

1、Petrochemical & Chemical Processing: Compression of highly corrosive intermediates, toxic reactants (e.g., in PVC production with Cl₂), catalyst regeneration gases, hydrogen compression for hydrocrackers/hydrotreaters where purity is critical.

2、Oil & Gas: Subsea gas compression, gas injection (enhanced oil recovery), hydrogen compression for refineries.

3、Semiconductor Manufacturing: Essential for supplying ultra-high purity (UHP) and hazardous specialty gases (like AsH₃, PH₃, SiH₄) to fabrication tools without contamination.

4、Analytical & Laboratory: Supplying pure, contaminant-free carrier gases, calibration gases, and sample gases for instruments like GC-MS.

5、Aerospace & Testing: High-pressure gas supply (He, N₂) for testing rocket components, pressurizing systems, wind tunnels.

6、Medical & Pharmaceutical: Production and bottling of high-purity medical gases (O₂, N₂O), sterile air for processes.

7、Nuclear Industry: Handling helium coolants or cover gases.

8、Energy & Hydrogen: Hydrogen compression for fuel cells, hydrogen refueling stations (HRS), and hydrogen production/storage research.

9、Environmental Technology: Compressing captured CO₂ for sequestration or utilization (CCUS).

|

Model

|

Cooling water (L/h)

|

Flow (Nm³/h)

|

Inlet pressure (MPa)

|

Outlet pressure (MPa)

|

Dimensions L×W×H(mm)

|

Weight (Kg)

|

Motor Power (kW)

|

|

|

1

|

GD-120/4-80 |

3000

|

120

|

0.4

|

8.0

|

3000×1600×1400

|

4000

|

30

|

|

2

|

GD-130/0.98-11 |

3000

|

130

|

0.098

|

1.1

|

3000×1800×1600

|

4000

|

30

|

|

3

|

GD-150/2-20 |

3000

|

150

|

0.2

|

2.0

|

3000×1800×1600

|

4000

|

37

|

|

4

|

GD-100/0.1-5 |

4000

|

100

|

0.01

|

0.5

|

2800×1500×1500

|

3000

|

18.5

|

|

5

|

GD-100/5.5-200 |

5000

|

100

|

0.55

|

20

|

3200×2000×1600

|

4500

|

45

|

|

6

|

GD-80/0.12-4 |

5000

|

80

|

0.012

|

0.4

|

2800×1600× 1500

|

3800

|

15

|

|

7

|

GD-60/0.3-6 |

4000

|

60

|

0.03

|

0.6

|

2800×1600×1500

|

4000

|

15

|

|

8

|

GD-70/0.1-8 |

,3800

|

70

|

0.01

|

0.8

|

3000×1600×1250

|

5000

|

18.5

|

|

9

|

GD-40/0.02-160 |

5000

|

40

|

0.02

|

16

|

2800×1460×1530

|

3000

|

22

|

|

10

|

GD-100/0.5-6 |

2000

|

100

|

0.05

|

0.6

|

3000×2000×1560

|

6000

|

18.5

|

|

11

|

GD-36/1-150 |

4000

|

36

|

0.1

|

15

|

3000×1500×1500

|

4000

|

45

|

|

12

|

GD-35/0.7-300 |

4000

|

35

|

0.07

|

30

|

3000×1600×1500

|

4000

|

22

|

We hold internationally recognized certifications including CE and ISO standards (accredited by IAF), as well as ECM compliance recognition. These certifications demonstrate our unwavering commitment to quality, safety, and environmental responsibility:

- CE Marking ensures compliance with EU safety, health, and environmental regulations, guaranteeing free market access across Europe.

- ISO Certification (backed by IAF accreditation) validates our adherence to globally benchmarked quality management systems, enhancing operational consistency and customer confidence.

- ECM Recognition underscores our alignment with industry-specific technical and performance standards.

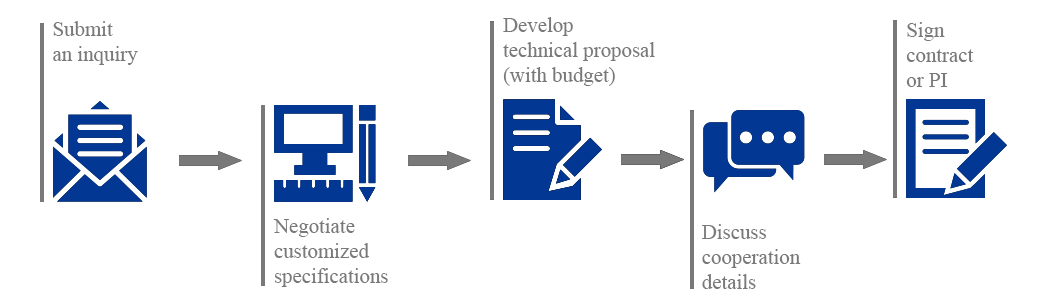

Should your market or project require additional certifications (e.g., API, ASME, or region-specific approvals), our experienced technical and compliance team will collaborate with you to efficiently obtain the necessary certifications. We tailor our processes to meet your regulatory requirements, ensuring seamless market entry for our equipment. For certification support or clarification, please contact us to discuss customized solutions.

Our 90,000+Square meter modern production facility, staffed by 120+ professionals, delivers customized engineering solutions with precision manufacturing capabilities. Equipped with 20 advanced CNC machining centers, we handle workpieces up to 1200mm in diameter with micron-level accuracy (0.01mm). Rigorous quality control protocols include full inspections of critical components using CMM (Coordinate Measuring Machines) and multi-phase load testing by certified engineers post-assembly. Every unit undergoes performance validation to comply with ASME/API standards and client specifications, backed by ISO 9001-certified quality management for traceable, reliable delivery.

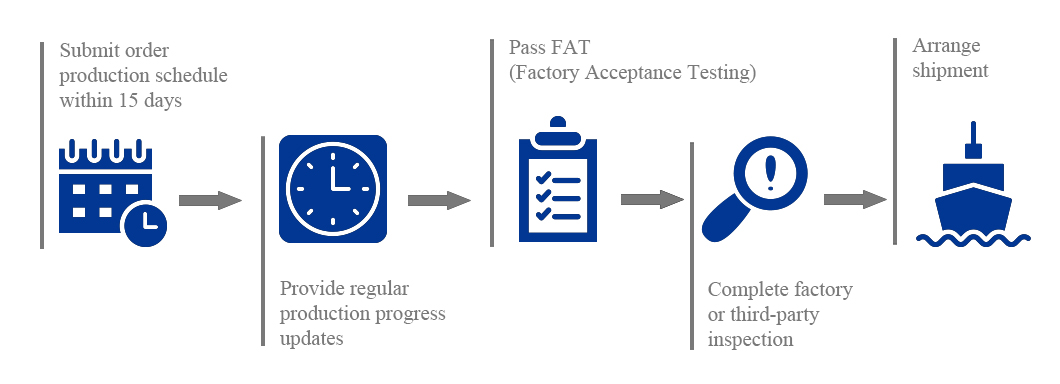

We utilize fumigation-free solid wood frameworks certified by ISO international export quarantine standards. Internally reinforced with channel steel for three-dimensional support, the exterior is wrapped with 0.8mm thickened metal corner guards and secured at joints using waterproof galvanized steel straps. This design ensures impact resistance, compression-proof durability, moisture protection, and rust prevention throughout transit, guaranteeing your goods arrive safely.

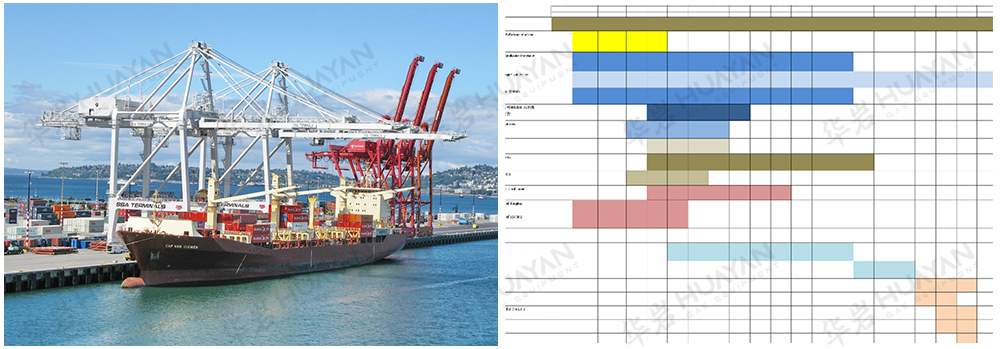

Our company will develop customized delivery schedules for your project, supported by integrated logistics solutions covering air, sea, and land transport.

Leveraging China's domestic network and global partnerships, we ensure efficient cross-border operations with real-time tracking, customs clearance support, and bonded warehousing capabilities. Multi-modal flexibility guarantees cost-effective and timely delivery for all cargo types.

1.How to get a prompt quotation of gas compressor ?

1)Flow Rate/Capacity : ___ Nm3/h

2)Suction/ Inlet Pressure : ____ Bar

3)Discharge/Outlet Pressure :____ Bar

4)Gas Medium :_____

5)Voltage and Frequency : ____ V/PH/HZ

2.How long is delivery time ?

Delivery time is around the 30-90 days .

3.What about the voltage of products? Can they be customized?

Yes, the voltage can be customized according to your inquire.

4.Can you accept OEM orders?

Yes, OEM orders is highly welcome.

5.Will you provide some spare parts of the machines?

Yes