Reciprocating Piston Type Hydrogen Gas Compressors for Fuel Filling Stations

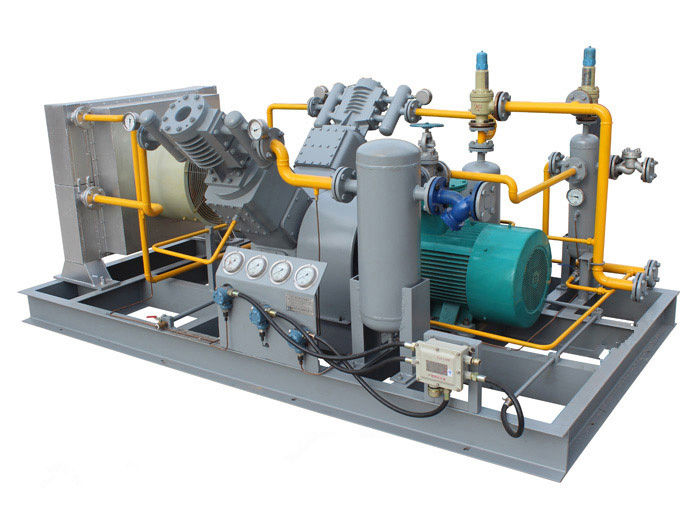

OILFIELD COMPRESSOR-REFERENCE PICTURE

Piston compressor is a kind of piston reciprocating motion to make gas pressurization and gas delivery compressor mainly consists of working chamber, transmission parts, body and auxiliary parts. The working chamber is directly used to compress the gas, the piston is driven by the piston rod in the cylinder for reciprocating motion, the volume of the working chamber on both sides of the piston changes in turn, the volume decreases on one side of the gas due to the pressure increase through the valve discharge, the volume increases on one side due to the reduction of air pressure through the valve to absorb the gas.

We have various gas compressors, such as Hydrogen compressor, Nitrogen compressor, Natrual gas compressor, Biogas compressor, Ammonia compressor, LPG compressor, CNG compressor, Mix gas compressor and so on.

Advantages of Hydrogen Gas Compressor:

1. High quality material, Stable & Reliable operation

2. Low Maintenance cost & Low noise

3. Easy to install on site and connect with the user's pipeline system to operate

4. Alarm automatic shutdown to protection machine function

5. High pressure and flow

Lubrication includes: oil lubrication and oil free lubrication;

The cooling method includes: water cooling and air cooling.

Installation type includes: Stationary, Mobile and Skid Mounting.

Type includes: V-type, W-type, D-type, Z-type

Product description

Hydrogen compressor

Application

This series of compressors are mainly used for (methanol, natural gas, coal gas) cracking hydrogen production, water electrolysis hydrogen production, hydrogen filling bottle, benzene hydrogenation, tar hydrogenation, catalytic cracking and other hydrogen booster compressors.

Product features:

1. The product has the characteristics of low noise, small vibration, compact structure, stable operation, safety and reliability, and high automation level. It can also be configured with a digital remote display and control system according to customer requirements.

2. It has the function of alarm and shutdown of low compressor oil pressure, low water pressure, high temperature, low intake pressure and high exhaust pressure, which makes the compressor run more reliable.

Structure introduction: The unit consists of compressor host, motor, coupling, flywheel, piping system, cooling system, electrical equipment, and auxiliary equipment.

|

No |

Model |

Gas flow (Nm3/h) |

Inlet pressure (Mpa) |

Outlet pressure (Mpa) |

Gas |

Power (kw) |

Dimensions (mm) |

|

1 |

ZW-0.5/15 |

24 |

Atmospheric pressure |

1.5 |

Hydrogen |

7.5 |

1600*1300*1250 |

|

2 |

ZW-0.16/30-50 |

240 |

3 |

5 |

Hydrogen |

11 |

1850*1300*1200 |

|

3 |

ZW-0.45/22-26 |

480 |

2.2 |

2.6 |

Hydrogen |

11 |

1850*1300*1200 |

|

4 |

ZW-0.36 /10-26 |

200 |

1 |

2.6 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

5 |

ZW-1.2/30 |

60 |

Atmospheric pressure |

3 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

6 |

ZW-1.0/1.0-15 |

100 |

0.1 |

1.5 |

Hydrogen |

18.5 |

2000*1350*1300 |

|

7 |

ZW-0.28/8-50 |

120 |

0.8 |

5 |

Hydrogen |

18.5 |

2100*1350*1150 |

|

8 |

ZW-0.3/10-40 |

150 |

1 |

4 |

Hydrogen |

22 |

1900*1200*1420 |

|

9 |

ZW-0.65/8-22 |

300 |

0.8 |

2.2 |

Hydrogen |

22 |

1900*1200*1420 |

|

10 |

ZW-0.65/8-25 |

300 |

0.8 |

25 |

Hydrogen |

22 |

1900*1200*1420 |

|

11 |

ZW-0.4/(9-10)-35 |

180 |

0.9-1 |

3.5 |

Hydrogen |

22 |

1900*1200*1420 |

|

12 |

ZW-0.8/(9-10)-25 |

400 |

0.9-1 |

2.5 |

Hydrogen |

30 |

1900*1200*1420 |

|

13 |

DW-2.5/0.5-17 |

200 |

0.05 |

1.7 |

Hydrogen |

30 |

2200*2100*1250 |

|

14 |

ZW-0.4/(22-25)-60 |

350 |

2.2-2.5 |

6 |

Hydrogen |

30 |

2000*1600*1200 |

|

15 |

DW-1.35/21-26 |

1500 |

2.1 |

2.6 |

Hydrogen |

30 |

2000*1600*1200 |

|

16 |

ZW-0.5/(25-31)-43.5 |

720 |

2.5-3.1 |

4.35 |

Hydrogen |

30 |

2200*2100*1250 |

|

17 |

DW-3.4/0.5-17 |

260 |

0.05 |

1.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

18 |

DW-1.0/7-25 |

400 |

0.7 |

2.5 |

Hydrogen |

37 |

2200*2100*1250 |

|

19 |

DW-5.0/8-10 |

2280 |

0.8 |

1 |

Hydrogen |

37 |

2200*2100*1250 |

|

20 |

DW-1.7/5-15 |

510 |

0.5 |

1.5 |

Hydrogen |

37 |

2200*2100*1250 |

|

21 |

DW-5.0/-7 |

260 |

Atmospheric pressure |

0.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

22 |

DW-3.8/1-7 |

360 |

0.1 |

0.7 |

Hydrogen |

37 |

2200*2100*1250 |

|

23 |

DW-6.5/8 |

330 |

Atmospheric pressure |

0.8 |

Hydrogen |

45 |

2500*2100*1400 |

|

24 |

DW-5.0/8-10 |

2280 |

0.8 |

1 |

Hydrogen |

45 |

2500*2100*1400 |

|

25 |

DW-8.4/6 |

500 |

Atmospheric pressure |

0.6 |

Hydrogen |

55 |

2500*2100*1400 |

|

26 |

DW-0.7/(20-23)-60 |

840 |

2-2.3 |

6 |

Hydrogen |

55 |

2500*2100*1400 |

|

27 |

DW-1.8/47-57 |

4380 |

4.7 |

5.7 |

Hydrogen |

75 |

2500*2100*1400 |

|

28 |

VW-5.8/0.7-15 |

510 |

0.07 |

1.5 |

Hydrogen |

75 |

2500*2100*1400 |

|

29 |

DW-10/7 |

510 |

Atmospheric pressure |

0.7 |

Hydrogen |

75 |

2500*2100*1400 |

|

30 |

VW-4.9/2-20 |

750 |

0.2 |

2 |

Hydrogen |

90 |

2800*2100*1400 |

|

31 |

DW-1.8/15-40 |

1500 |

1.5 |

4 |

Hydrogen |

90 |

2800*2100*1400 |

|

32 |

DW-5/25-30 |

7000 |

2.5 |

3 |

Hydrogen |

90 |

2800*2100*1400 |

|

33 |

DW-0.9/20-80 |

1000 |

2 |

8 |

Hydrogen |

90 |

2800*2100*1400 |

|

34 |

DW-25/3.5-4.5 |

5700 |

0.35 |

0.45 |

Hydrogen |

90 |

2800*2100*1400 |

|

35 |

DW-1.5/(8-12)-50 |

800 |

0.8-1.2 |

5 |

Hydrogen |

90 |

2800*2100*1400 |

|

36 |

DW-15/7 |

780 |

Atmospheric pressure |

0.7 |

Hydrogen |

90 |

2800*2100*1400 |

|

37 |

DW-5.5/2-20 |

840 |

0.2 |

2 |

Hydrogen |

110 |

3400*2200*1300 |

|

38 |

DW-11/0.5-13 |

840 |

0.05 |

1.3 |

Hydrogen |

110 |

3400*2200*1300 |

|

39 |

DW-14.5/0.04-20 |

780 |

0.004 |

2 |

Hydrogen |

132 |

4300*2900*1700 |

|

40 |

DW-2.5/10-40 |

1400 |

1 |

4 |

Hydrogen |

132 |

4200*2900*1700 |

|

41 |

DW-16/0.8-8 |

2460 |

0.08 |

0.8 |

Hydrogen |

160 |

4800*3100*1800 |

|

42 |

DW-1.3/20-150 |

1400 |

2 |

15 |

Hydrogen |

185 |

5000*3100*1800 |

|

43 |

DW-16/2-20 |

1500 |

0.2 |

2 |

Hydrogen |

28 |

6500*3600*1800 |

Customized is accepted. Please provide the following information to us, then we will do the technical proposal and best price to you.

1. Flow rate: _______Nm3/h

2. Gas Media: ___ Hydrogen or Natural Gas or Oxygen or other gas

3. Inlet pressure: ___bar(g)

4. Inlet temperature: _____ºC

5. Outlet pressure: ____bar(g)

6. Outlet temperature: ____ºC

7. Installation location: __indoor or outdoor

8. Location ambient temperature: ____ºC

9. Power supply: _V/ _Hz/ _3Ph

10. Cooling method for gas: air cooling or water cooling

Picture display

Company strength display

After Sales Service

1.Quick response within 2 to 8 hours, with a reaction rate exceeding 98%;

2. 24-hour telephone service, please feel free to contact us;

3. The whole machine is guaranteed for one year (excluding pipelines and human factors);

4. Provide consulting service for the service life of the whole machine, and provide 24-hour technical support via email;

5. On-site installation and commissioning by our experienced technicians;

FAQ

1.How to get a prompt quotation of gas compressor ?

1)Flow Rate/Capacity : ___ Nm3/h

2)Suction/ Inlet Pressure : ____ Bar

3)Discharge/Outlet Pressure :____ Bar

4)Gas Medium :_____

5)Voltage and Frequency : ____ V/PH/HZ

2.How long is delivery time ?

Delivery time is around the 30-90 days .

3.What about the voltage of products? Can they be customized?

Yes, the voltage can be customized according to your inquire.

4.Can you accept OEM orders?

Yes, OEM orders is highly welcome.

5.Will you provide some spare parts of the machines?

Yes, we will .

OILFIELD COMPRESSOR-PARAMETER TABLE

|

Oilfield Piston Compressor Parameter Table |

||||||

|

|

Model |

Flow-rate (Nm³/h) |

Intake pressure(MPa) |

Exhaust pressure(MPa) |

Rotor power (kw) |

Dimensions L×W×H(mm) |

|

1 |

ZW-1.2/0.01-(35-40) |

60 |

0.001 |

3.5-4.0 |

15 |

1000×580×870 |

|

2 |

ZW-0.4/ 2-250 |

60 |

0.2 |

25 |

18.5 |

2800×2200×1600 |

|

3 |

DW-6.4/0.5-2 |

500 |

0.05 |

0.2 |

22 |

2100×1600×1350 |

|

4 |

DW-7.4/(0-0.5)-2 |

480 |

0-0.05 |

0.2 |

30 |

2100×1600×1350 |

|

5 |

DW-5.8/0.5-5 |

400-500 |

0.05 |

0.5 |

37 |

2100×1600×1350 |

|

6 |

DW-10/2 |

510 |

Normal |

0.2 |

37 |

2100×1600×1350 |

|

7 |

VW-1.1 / 2-250 |

170 |

0.2 |

25 |

45 |

3400×2100×1600 |

|

8 |

DW-2.05/(5-9)-20 |

625 |

0.5-0.9 |

2 |

55 |

2200×1600×1200 |

|

9 |

VW-25/(0.2-0.3)-1.5 |

1620 |

0.02-0.03 |

0.15 |

75 |

2400×1800×1500 |

|

10 |

DW-1.75/2-200 |

270 |

0.2 |

20 |

75 |

3400×2200×1600 |

|

11 |

VW-19.20/0.5-3.5 |

1500 |

0.05 |

0.35 |

110 |

3400×2200×1300 |

|

12 |

DW-9.1/0.05-32 |

500 |

0.005 |

3.2 |

110 |

3400×2200×1300 |

|

13 |

DW-0.48/40-250 |

900 |

4 |

25 |

110 |

3500×2200×1600 |

|

14 |

DW-6.0/(1-3)-25 |

840 |

0.1-0.3 |

2.5 |

132 |

4200×2200×1500 |

|

15 |

DW-13.5/(1-3)-(5-7) |

2040 |

0.1-0.3 |

0.5-0.7 |

132 |

4200×2200×1500 |

|

16 |

VW-6.7/2-25 |

1020 |

0.2 |

2.5 |

160 |

4500×2800×1500 |

|

17 |

DW-6.71 /5-30 |

2083 |

0.5 |

3 |

185 |

5500×3200×1600 |

|

18 |

VW-2.6/5-250 |

800 |

0.5 |

25 |

185 |

5500×3200×1600 |

|

19 |

DW-67/1.5 |

3420 |

Normal |

0.15 |

185 |

5500×3200×1600 |

|

20 |

DW-1.4/20-250 |

1440 |

2 |

25 |

220 |

5800×3200×1600 |

|

21 |

DW-0.9/40-250 |

1860 |

4 |

25 |

110 |

4000×2200×1580 |

|

22 |

DW-34/1.04-8.5 |

3540 |

0.104 |

0.85 |

315 |

6500×4500×1600 |

SUBMIT INQUIRY PARAMETERS

If you want us to provide you with detailed technical design and quotation, please provide the following technical parameters, and we will reply to your email or phone within 24 hours.

1.Flow: _____ Nm3 / hour

2.Inlet pressure: _____Bar(MPa)

3.Outlet pressure: _____Bar(MPa)

4. Gas medium: _____

We can customize a variety of compressors. Please send the above parameters to email: Mail@huayanmail.com